The manufacturing industry has been rocky over the past year, as it had to navigate choppy waters to stay afloat cost-wise due to issues such as global conflict and tariffs.

In addition to the duty fees, manufacturers also had to remain compliant with the ever-changing federal and state regulations, which at times are at opposite ends of the spectrum.

Additionally, more are turning to artificial intelligence to help reduce costs and streamline and accelerate production.

Here are some of the top trends we're following in the new year. If there are any trends Manufacturing Dive should keep an eye out for, email us at [email protected].

Tariff uncertainty continues in the manufacturing industry

U.S. manufacturing activity decreased to its lowest point of 2025 in December due to ongoing tariff uncertainty and weak demand, according to the Institute for Supply Management’s latest Purchasing Managers’ Index.

Manufacturers have had to raise prices, modify operations and implement layoffs to cut costs and stay afloat. Unfortunately, tariff uncertainty isn’t going away anytime soon. Since President Donald Trump returned to the White House, his administration has announced and implemented tariffs on many categories of goods — including steel, agricultural products and automotive components — and previewed more to come.

As to when the industry can breathe a sigh of relief, that will depend on what the U.S. Supreme Court decides. In November, the Supreme Court heard oral arguments on the legality of Trump’s exercise of presidential power under the International Emergency Economic Powers Act, which allows the president to impose unrestricted tariffs after declaring a national emergency.

While the justices were skeptical of the government’s interpretation of the IEEPA, manufacturers will have to wait for the court’s final decision, which may come as soon as Jan. 9.

If the Supreme Court rules against the administration's position, companies can apply for refunds, as long as they document any duties they paid under the IEEPA. The court could also keep some tariffs in place and throw others out.

Manufacturing investments continue to grow

A mix of policy incentives and continued demand for semiconductors and components supporting the data center boom are likely to be big drivers for manufacturing investment growth heading into the new year. While tariffs and shifting supplier dynamics are pressuring foreign companies to establish footholds in the U.S., how that is affecting reshoring is up for debate.

The One Big Beautiful Bill Act retained the 21% corporate tax rate and made permanent a number of tax-saving provisions, including full expensing for new equipment and immediate expensing of domestic research and development.

The Trump administration also released its AI Action Plan over the summer, which could spur construction of data centers and semiconductor fabrication sites by removing regulatory barriers and expediting permits. House lawmakers passed a permit reform bill last month that would ease building of AI infrastructure. The Senate took up the issue before the holiday break, and talks are likely to pick up in the near future.

Additionally, Congress last month passed the National Defense Authorization Act, approving billions of dollars for defense-related manufacturing and emerging technologies.

Data center growth has already driven significant investment across manufacturing and is expected to continue this year. Several companies with multi-year agreements to produce transformers, switchgear, power management equipment and other key data center components have already sold out, according to Deloitte. Others have signaled plans to expand production to meet demand.

Chipmaking is also poised to grow. As of July 2025, companies have committed more than $500 billion in private sector investments to bolster the chipmaking sector, according to the Semiconductor Industry Association. This is expected to support more than 500,000 U.S. jobs and help triple domestic capacity by 2032.

Additionally, merger and acquisition activity is set to increase. Two-thirds of U.S. business leaders plan to do more M&A deals this year, spurred by further interest rate cuts and lower taxes, according to a recent survey released by accounting and consulting firm KPMG.

Factors like the Trump administration’s “Liberation Day” tariffs in April and the government shutdown stoked uncertainty among dealmakers, according to KPMG’s report. Since then, leaders have grown accustomed to the “new normal” and are moving ahead with M&A deals all the same. More foreign companies are also reaching out to brokers in hopes of securing a foothold in the U.S.

Workforce transformation to support smart manufacturing

It’s no secret that one of the biggest challenges facing manufacturers is filling the talent skills gap. As companies invest in and implement advanced technologies on their factory floors, they are also searching for workers with the skills and knowledge to handle tasks for the next generation of manufacturing.

To help bridge the gap nationwide, the Department of Labor will continue pouring millions of dollars into state workforce development programs with a focus on advanced manufacturing. Last month, the agency announced the availability of $98 million to support education and training for in-demand industries. Additionally, companies will continue to invest in their own training programs or partnerships with institutes and community colleges.

In October, the GE Aerospace Foundation said it will invest $30 million over the next five years in a new training program with the goal of increasing the number of highly skilled U.S. workers by 10,000 starting in 2026. Companies like Flex and Siemens have also agreed to each provide $1.5 million over a three-year period to support the Massachusetts Institute of Technology’s Initiative for New Manufacturing, which aims to support job creation.

By 2033, U.S. manufacturers may need as many as 3.8 million new workers, according to a 2024 report from Deloitte and the Manufacturing Institute. However, issues around attracting, retaining and finding talent have plagued the industry. Researchers predict as many as 1.9 million jobs could remain unfilled if manufacturers are unable to address the skills and applicant gaps.

The makeup of the manufacturing workforce is also shifting. Production roles, healthcare support, grounds cleaning and low-wage occupations have all declined incrementally between 2024 and 2025, according to Bureau of Labor Statistics data compiled by Deloitte. The decline largely stemmed from automation, new technology and higher outsourcing of jobs.

Simultaneously, high-tech, high-wage manufacturing has gained ground, and the trend is likely to continue.

AI and digital tool adoption to accelerate

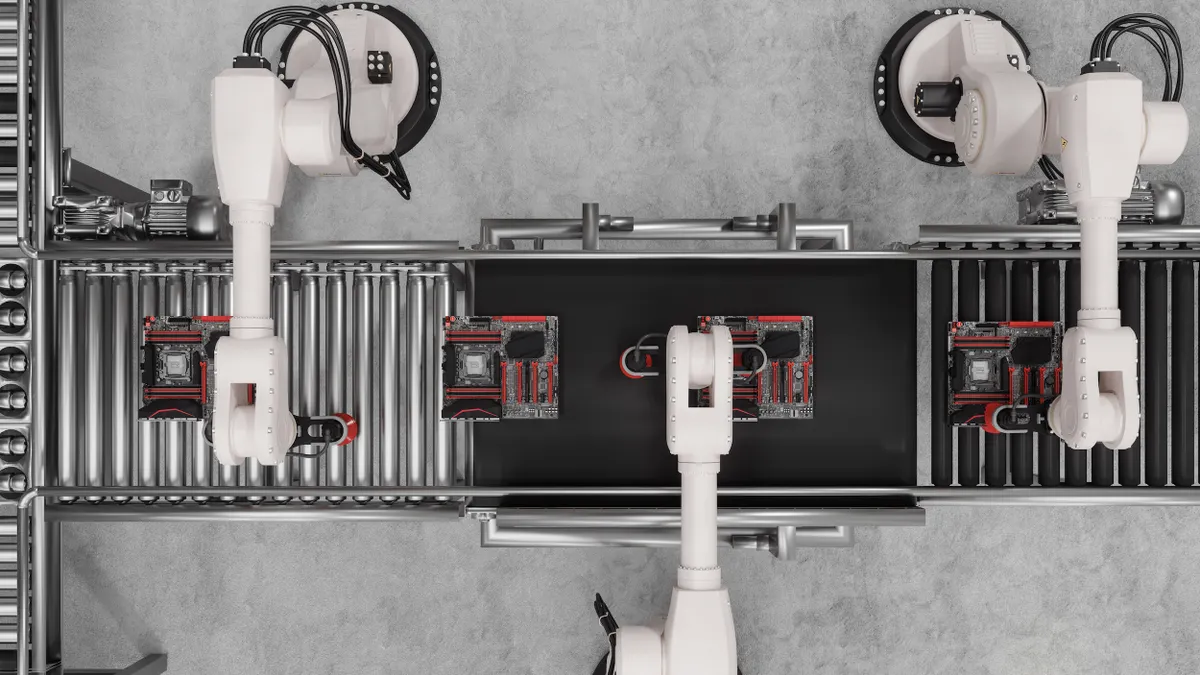

To address labor shortages and remain competitive, U.S. manufacturers are looking to implement and scale the latest technologies across their operations as tariffs and trade uncertainty continue.

According to Deloitte’s 2025 survey, the vast majority plan to invest 20% or more of their improvement budgets on smart manufacturing initiatives, including automation hardware, data analytics, sensors and cloud computing.

Participants said they viewed smart manufacturing as the “primary driver of competitiveness" over the next three years, with the potential to unlock benefits such as improved output, employee productivity and capacity.

As companies navigate trade uncertainty and higher costs, sourcing challenges are likely to persist. Manufacturers have begun leveraging agentic AI, which can autonomously reason and make decisions without human input, to mitigate such challenges. Many are already using large language models and agents to navigate trade risks and identify potential cost savings.

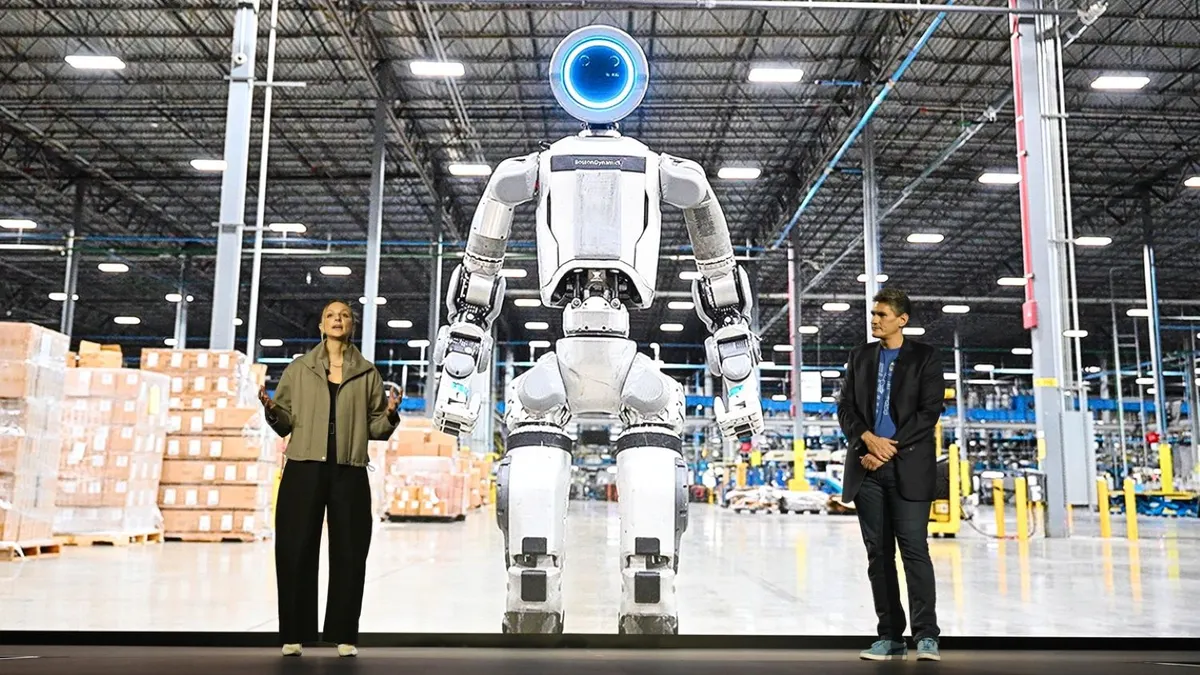

Agentic AI is expected to generate up to $650 billion in additional revenue by 2030 across industries, according to McKinsey research from September. Simultaneously, automation of repetitive tasks could yield up to 50% in cost savings. The technology also lays the groundwork for physical AI, or robots with autonomy.

According to a survey conducted by the Manufacturing Leadership Council last year, about 22% of manufacturers plan to use physical AI by 2027, including robotic dogs and humanoids to accomplish sorting, transporting and other tasks.

Foxconn, a contract electronics manufacturer, has already begun reshaping its operations into what it calls a “scalable, AI-powered workforce” that leverages AI and digital twin technology for its robots in response to labor costs and shortages, according to a September white paper from the World Economic Forum.

While intelligent robotics is still a growing field, early adopters are reaping the benefits of the technology, and more investment is likely to come. Caterpillar this week announced at CES in Las Vegas that it will team with Nvidia to equip its machines, job sites and factories with AI to create “safer, leaner, more resilient production systems.”

Expect to see chemical regulation changes, state and federal

Last year, the U.S. EPA launched an extensive deregulation effort comprising 31 actions aimed at reducing federal oversight of climate-related rules.

The actions affect various industries, including manufacturing, and are part of EPA Administrator Lee Zeldin’s “Powering the Great American Comeback” initiative that aims to create more jobs and grow the U.S. economy. However, it will be a while before changes are finalized, as it could take months or years for the agency’s efforts to come into fruition.

Since the March 2025 announcement, the agency has proposed rules modifying various regulations finalized under the Biden administration, particularly mandates under the Toxic Substances Control Act.

However, chemical manufacturers are pushing for TSCA reform on the chemical review process. Trade groups such as the American Chemistry Council are asking Congress to reform the law as it reauthorizes EPA’s ability to collect fees from companies.

Trade groups have said the chemical review process has taken longer than the estimated 90 days and that risk evaluations included scenarios they deemed impractical and not science-based.

Additionally, Douglas Troutman has now been confirmed to lead the EPA’s Office of Chemical Safety and Pollution Prevention. Troutman said at his Senate confirmation hearing in October 2025 that he would work with Congress to address any gaps in TSCA.

While the EPA and Congress work to reform and alleviate federal chemical regulations, states have enacted laws to ban or regulate chemicals, such as perfluoroalkyl and polyfluoroalkyl substances.

While the federal government is modifying chemical regulations, state legislators have forged ahead with new laws over the past few years, with some taking effect in 2026.

Coming into the new year, state lawmakers have begun introducing more bills to establish or expand government oversight.

Florida lawmakers have introduced state house and senate bills to ban aqueous firefighting foam containing PFAS. Massachusetts’ house representatives introduced a bill that aims to ban products such as food packaging, cookware and personal care containing PFAS as well as establish a reporting requirement. And New Hampshire legislators introduced a bill that could ban condoms made with the “forever chemicals.”