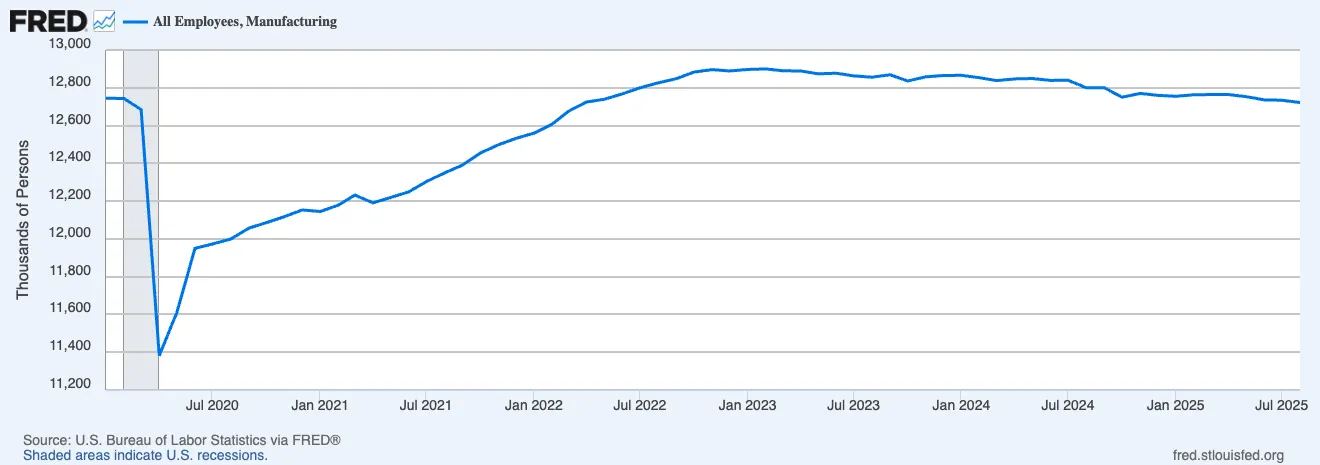

The U.S. manufacturing industry lost 78,000 jobs over the past year with 12,000 cuts in August alone, according to the latest federal data. This comes as automation is ramping up in factories, but it’s far from the only factor.

While the September employment data isn’t available yet due to the government shutdown, the August 2025 labor turnover survey shows a 12% dip in job openings compared to last year, with 313,000 job separations in manufacturing.

Experts say this isn’t new. Manufacturing jobs have been declining since February 2023, now reaching the lowest level since the onset of the COVID-19 pandemic.

The numbers have been going down since 1979. Now, factors such as the increasing use of AI and automation, tariff changes, tightening immigration policies, and an aging workforce are leading to further decline.

AI and automation

Manufacturing companies have been facing a labor shortage for years. Nearly 2 million jobs — half of all new positions created — could be unfilled by the end of the decade, according to data from Deloitte and The Manufacturing Institute.

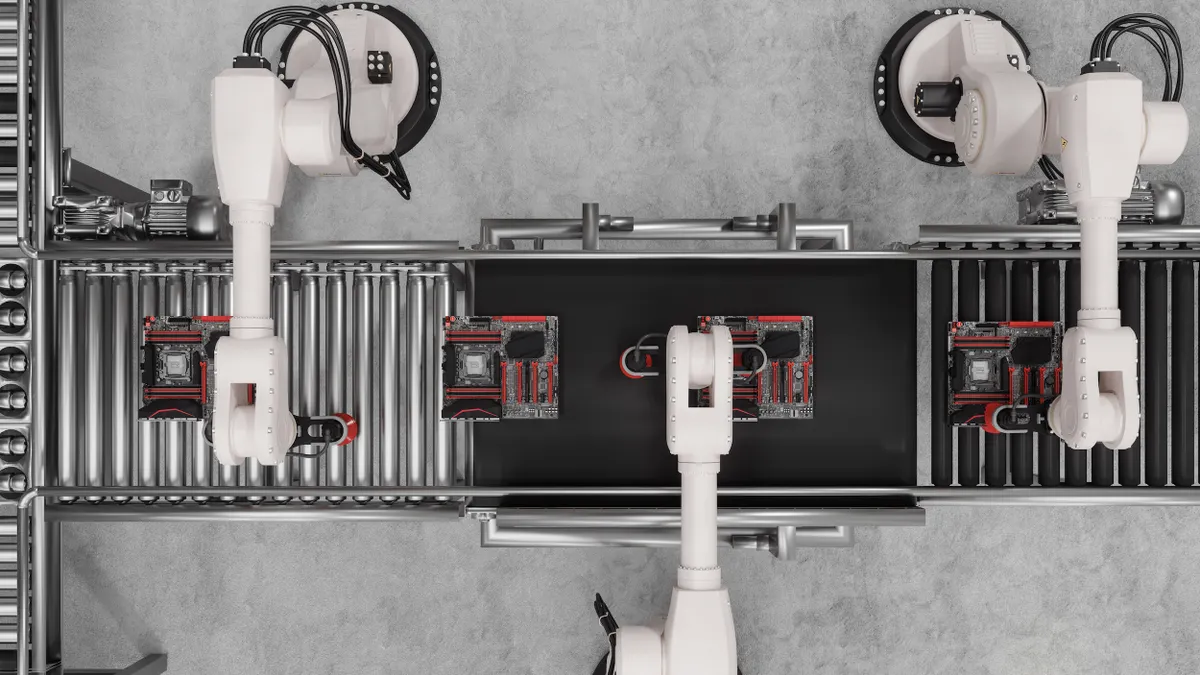

Many companies have turned to artificial intelligence and automation to bridge the gap, with some countries like China and Japan running fully automated factories. Some plants in the U.S., like Tesla’s Gigafactories, are also implementing similar models.

Sectors with high-volume production and repetitive tasks, such as automotive, semiconductors, electronics, aerospace and pharmaceuticals, are experiencing the highest adoption of AI and automation. Experts say other divisions will follow suit as implementing this technology becomes more accessible and financially viable.

While this has helped keep operations running as manufacturers struggle to hire and retain workers, it raises the question of what happens to the labor force replaced by machines. Is technological advancement stealing people’s jobs?

According to the latest SHRM analysis, 15% of jobs in the U.S. across all industries, about 23 million total, are at a high risk of being displaced due to automation.

Many experts point to reskilling as a solution, saying workers’ responsibilities could change rather than be completely eliminated.

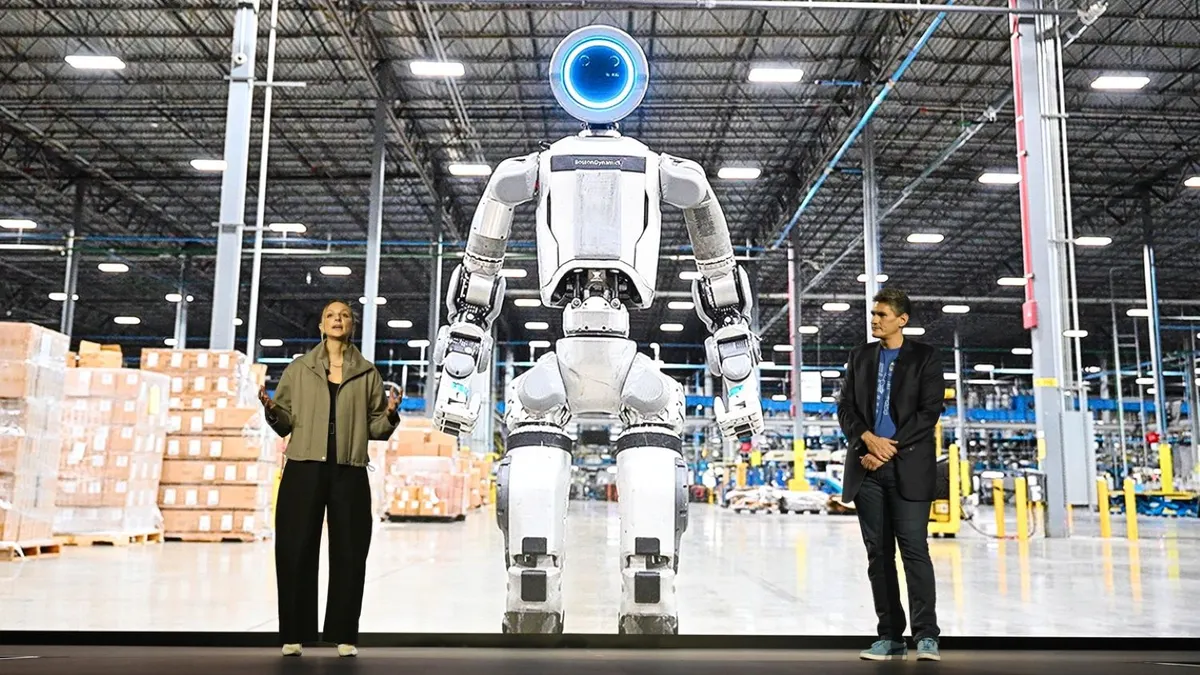

“Factories will keep getting smarter and more automated, but people will not disappear from the equation,” said Janelle Bieler, U.S. head of tech talent solutions at Akkodis, a digital engineering consulting company that is part of The Adecco Group.

“The larger shift is that there are not just fewer jobs, but different jobs,” she said. “Traditional assembly roles are declining while demand is growing for technicians who can work with robotics, maintain advanced equipment and use data to keep production running smoothly.”

Due to this, even though automation is making some positions redundant it’s also creating new roles that didn’t exist before.

Several programs, including the Akkodis Academy, are offering resources to support this transition. But many manufacturers aren’t in a position to make drastic changes.

“This transition will be more gradual as not all companies can afford to invest in automation so there will still be a need for people to support manufacturing, especially for small and medium enterprises where investment capital is scarce,” said Sumeet Kaul, a managing director in FTI Consulting’s corporate finance and restructuring segment.

“Reskilling is a potential solution but we need to remember that this is not a one-to-one replacement,” said Kaul.

This means a lot of jobs will continue to be replaced by machines, said Wafa Hakim Orman, associate dean of the College of Business and associate professor of economics at the University of Alabama in Huntsville, noting that this has happened before.

“In 1870, over half the U.S. labor force worked in agriculture but today, it's less than 2%,” said Orman.

The labor force moved into manufacturing and services as agriculture mechanized. Orman said we should expect to see the same pattern continue in manufacturing, where factories are increasingly automated, and reducing the reliance on human labor.

While some workers are being reskilled to work on these automation systems, the only option for others might be transitioning to a different industry.

Tariffs and tighter immigration policies

While AI and automation are bringing long-term changes that will change the very core of how the manufacturing industry operates, two other factors have also affected production this year.

First, the uncertainty around tariff policies has put some manufacturers in a “wait-and-see” mode, leading to stalled projects and hiring freezes, industry experts said.

“Exporters can't forecast demand, importers are uncertain about the price and how much of the tariffs consumers and foreign suppliers will bear, and manufacturers who use imported materials, tools, or components are dealing with large swings in their costs,” Orman said. It is difficult for businesses to plan long-term investments in such a volatile environment, she added.

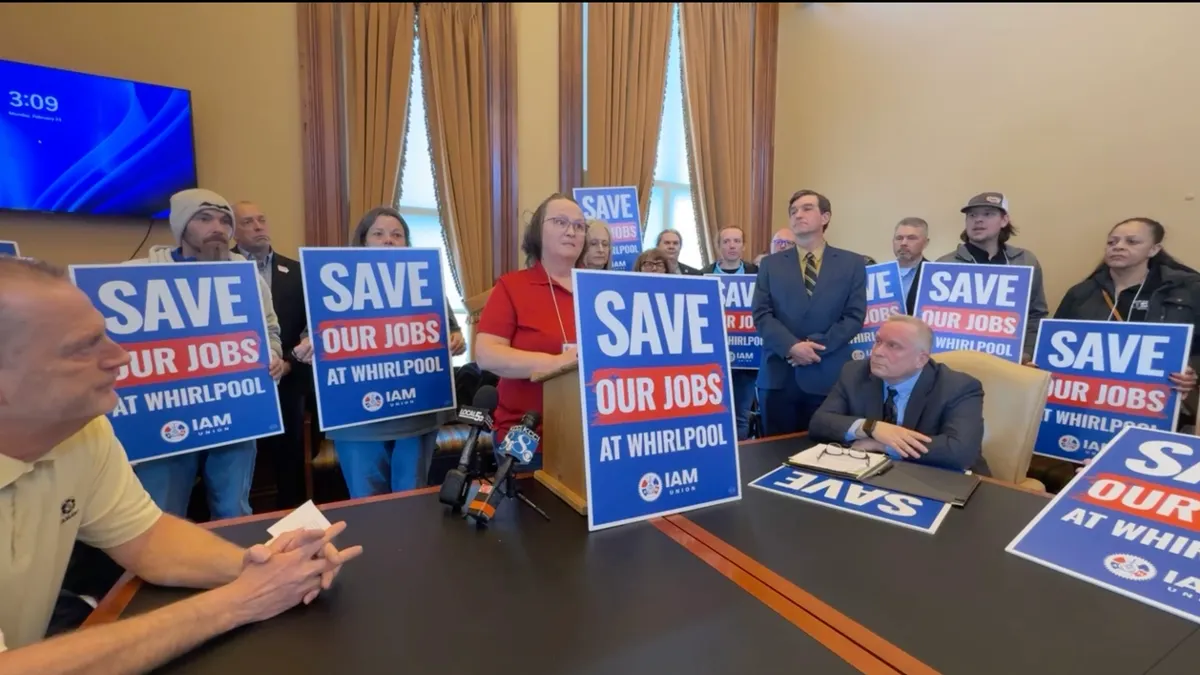

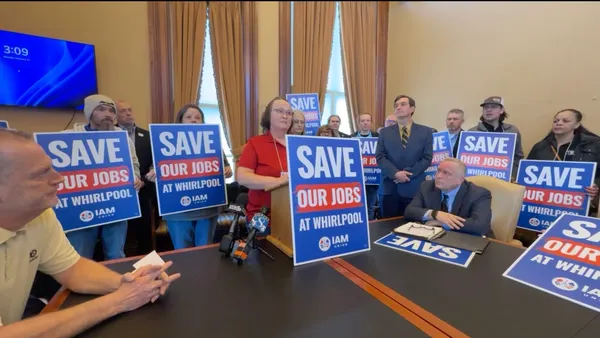

Amidst the recent policy changes, some plants have shut down, paused operations, changed locations, consolidated or discontinued certain production lines, all of which contributed to layoffs.

Second, President Donald Trump’s administration has implemented several changes to tighten immigration policies, making it harder for new foreign workers to enter and for those already here to stay. Some of these changes include a $100,000 fee for new H-1B visas, increased scrutiny of visa applicants’ social media activity, plans to end birthright citizenship, limiting access to health insurance benefits, and additional funding for detention and deportation.

There’s also been an increase in U.S. Immigration and Customs Enforcement raids at major facilities, such as the Hyundai plant in Georgia, where nearly 500 foreign workers were detained in September. Some factories across the country have reported delayed shipments and reduced production as a result.

The administration’s stated goal is to prioritize domestic hiring. Orman said this could possibly increase hiring, but it could also boost the pace of automation as some firms replace immigrant workers with machines, especially if local workers expect higher wages.

All of this has made 2025 an unpredictable year for manufacturers, with experts forecasting many more changes ahead.

“In the long run, new technology has typically made us more productive,” Orman said, “but in the short run, it can lead to significant disruption as people need to switch industries or occupations, and frequently retrain and learn new skills.”

Akkodis’ Bieler said this will require ongoing adaptability by all involved.

“The best safeguard for both workers and employers is steady investment in skills, so people are prepared to move into the roles that the market continues to demand,” she said. “Jobs will disappear, yes, but history shows us that new jobs always take their place.”