In the high-stakes world of automotive manufacturing, every minute counts. Downtime is costly, inefficiency is unacceptable, and safety is non-negotiable. So when a leading automaker installed Concentric®’s PowerHIVE™ forklift battery reload system in just three days, they saw immediate improvements in productivity, sustainability, and safety. No one expected an autonomous power management solution, typically a complex and lengthy integration, to deploy effortlessly, deliver instant ROI, and transform operations overnight. Now, other manufacturers are racing to replicate their success.

The Forklift Power Problem: A Hidden Bottleneck

Forklift fleets are the unsung heroes of manufacturing and distribution but powering them has long been a logistical headache. Whether using lead-acid, TPPL, lithium-ion, or hydrogen fuel cells, each battery type requires more cost and operator attention than their power equipment deserves.

Facility managers often find themselves stuck in a cycle of compromise, choosing between battery types that still require charging infrastructure, operator training, and maintenance. The result? Lost productivity, higher energy costs, and constrained equipment flexibility.

Enter PowerHIVE™: Autonomous Power Management Without the Overhead

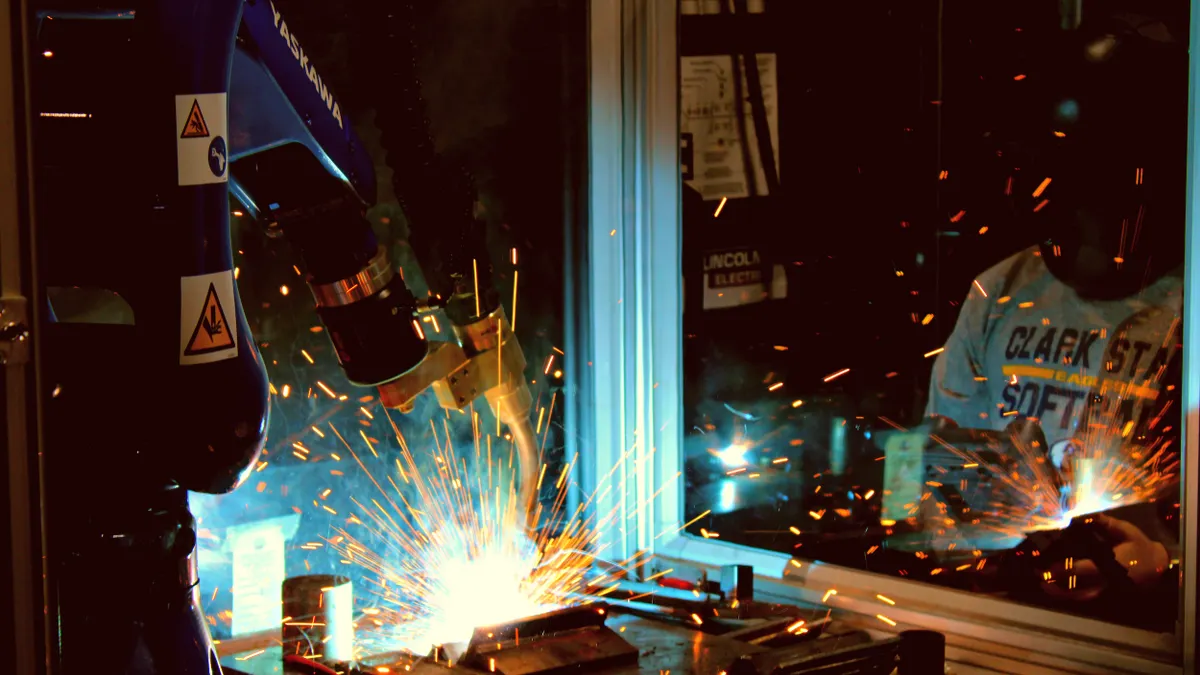

The PowerHIVE™ battery reload system is a complete reimagining of how forklift fleets are powered. Developed by Concentric®, the system delivers autonomous battery replacement using intelligent robotics and AI to eliminate manual handling and infrastructure headaches.

Operators simply park their equipment and stand on a weight-sensitive mat. At the push of a button, PowerHIVE™ scans the vehicle, selects the optimal battery, and deploys a robotic arm to swap it out. The depleted battery is docked into a smart charging station that recharges during off-peak hours, optimizing energy usage and extending battery life. The entire process takes less than three minutes.

Experience Quick Transformation Instead of Lengthy Integration

Unlike traditional automation projects that require months of planning, PowerHIVE™ installs in just three days. No infrastructure overhauls. No IT integration. Just one electrical drop and 15 minutes of operator training. One operations manager summed it up: “I’ve never seen anything that technological be so simple.”

This streamlined deployment model means facilities can start seeing ROI right away. Productivity gains are immediate, and the system scales easily across multiple sites.

Measurable Impact That Matters

For a 20-truck fleet running three shifts Monday through Friday, PowerHIVE™ delivers:

- 10% increase in pallet throughput

- 118 metric tons of carbon reduced annually

- 20,000+ equipment charging hours saved in the first year

These aren’t theoretical benefits. They’re real-world results, and the larger the fleet, the greater the return. Facilities reclaim floor space by eliminating battery rooms, reduce dwell time, and improve operator satisfaction. Most importantly, they create safer workplaces by removing the hazards of manually handling heavy batteries and damaged charging cables.

Peak Performance Without Peak Power Costs

PowerHIVE™ transforms energy management and creates an easy path toward ESG goals. By scheduling charging during off-peak utility hours, facilities avoid peak demand charges that can inflate energy bills. Peak charges are based on the highest 15-minute interval of electricity use during a billing cycle. PowerHIVE™ flattens the energy load profile, reducing costs and exposure to unpredictable fees. Operations in power-scarcity states can see even greater benefits. By shifting forklift charging to off-peak hours and automating the process, facilities can reallocate finite power resources to other, more demanding automations to maximize uptime without overloading the grid.

Powered by Concentric®: 25+ Years of Innovation

Concentric® has been solving motive power challenges for over 25 years. With a national footprint and more than 1,000 employees, Concentric is the industry’s leading facility partner for forklift power systems, critical power infrastructure, and full-time on-site automation maintenance. As TJ Shelters, Senior Vice President at Concentric®, puts it:

“We don’t focus on battery type. We deliver improved throughput. It’s about more pallets or units moving more efficiently to impact the customer’s P&L on day one. Customers see up to 10% improvement in throughput without changing anything for their operators.”

The Industry is Buzzing Over the ‘HIVE

Since its release in 2023, PowerHIVE™ has completed over 200,000 battery reloads in customer facilities across the U.S. and earned multiple top industry awards including the 2025 MHI Innovation Award and 2024 Product of the Year honors from Material Handling Product News and Plant Engineering.

Across industries from automotive to food and beverage, PowerHIVE™ offers a rare opportunity: a scalable, intelligent autonomous power solution that installs quickly, delivers immediate results, and simplifies operations. In a world where automation often means complexity, PowerHIVE™ delivers simplicity. And in a market where power management is a persistent challenge, PowerHIVE™ offers a permanent solution.