As robotics and artificial intelligence continue to advance, companies are clamoring for chips to support their research and development.

U.S.-based chipmakers GlobalFoundries, Onsemi and Diodes reported third quarter earnings that showed increased demand for their products to support physical AI and data center expansion as well as advancements in automobiles. Tariffs, meanwhile, are forcing many across the industry to retool their operational footprints to mitigate disruptions and higher trade costs.

Here are some key takeaways from the companies’ recent results.

The next phase of AI will accelerate sales demand

The progression of AI technology from generative to agentic and beyond is driving strong demand for semiconductor manufacturing. For years, the technology has been used primarily for white-collar jobs, with the advent of ChatGPT and other large language models accelerating processes. As advancements in robotics and AI infrastructure continue, chip makers are confident they are well positioned for the future.

“We believe the ongoing data center AI build-out is merely a prelude to the next step of the AI revolution: real-world applications in the physical space,” GlobalFoundries CEO Timothy Breen said on an earnings call Nov. 12.

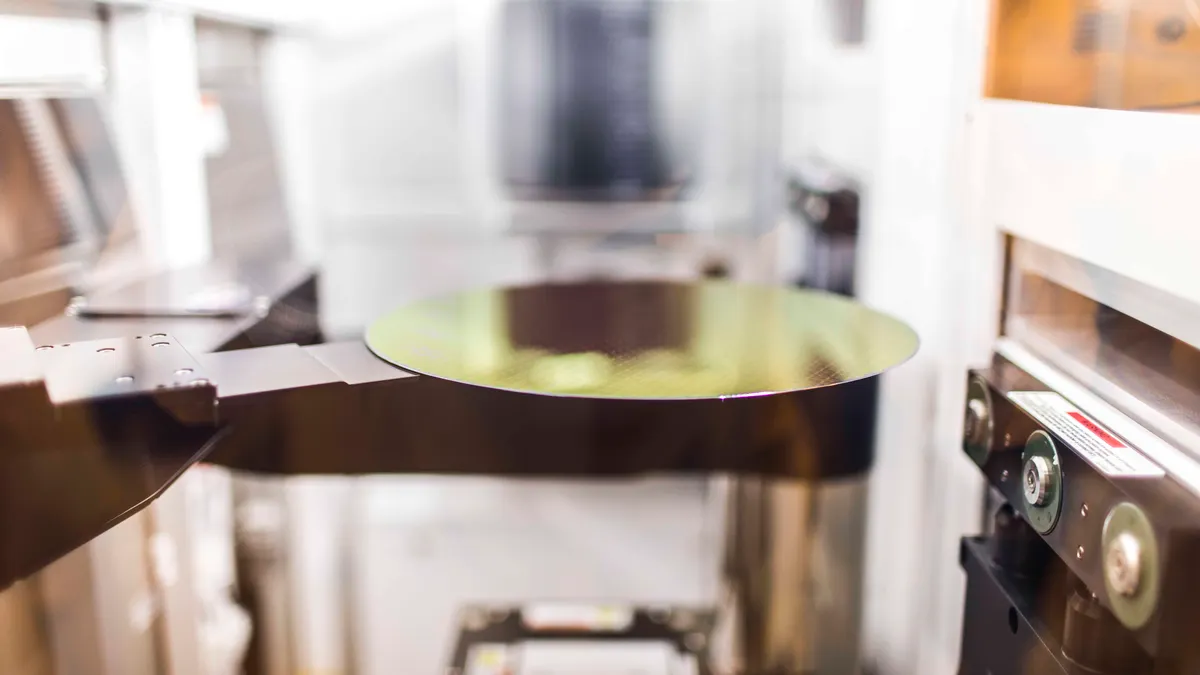

While GlobalFoundries primarily sells chips to customers making smart mobile devices, the data center boom has been huge for the company this year, according to its latest earnings presentation. In Q3, the chipmaker’s communications infrastructure and data center unit reported a 32% revenue increase to $175 million from a year ago.

Meanwhile, revenue for the company’s major markets smart mobile devices and home and industrial internet-connected devices, declined 13% and 16%, respectively. The markets accounted for 45% and 15% of the quarter’s total revenue, respectively. Despite its growth, communications infrastructure and data centers represented roughly 10% of GlobalFoundries’ quarterly revenue.

Malta, New York-based GlobalFoundries reported total Q3 revenue of nearly $1.7 billion, a 3% decline from last year. Net income surged to $249 million for the period, up 40% YoY.

On the call, Breen said the physical AI market will be key for the company moving forward. He estimated GlobalFoundries’ serviceable addressable market to surpass $18 billion by 2030.

“In the world of physical AI, the market will need vast amounts of feature-rich, low-power connected chips that are secure and cost effective,” Breen said, adding later that the company’s product portfolio “enables us to play a critical role in this coming revolution.”

GlobalFoundries’ chips are produced at four manufacturing sites across the world: Dresden, Germany; Singapore; Malta, New York; and Burlington, Vermont.

Automotive market growth

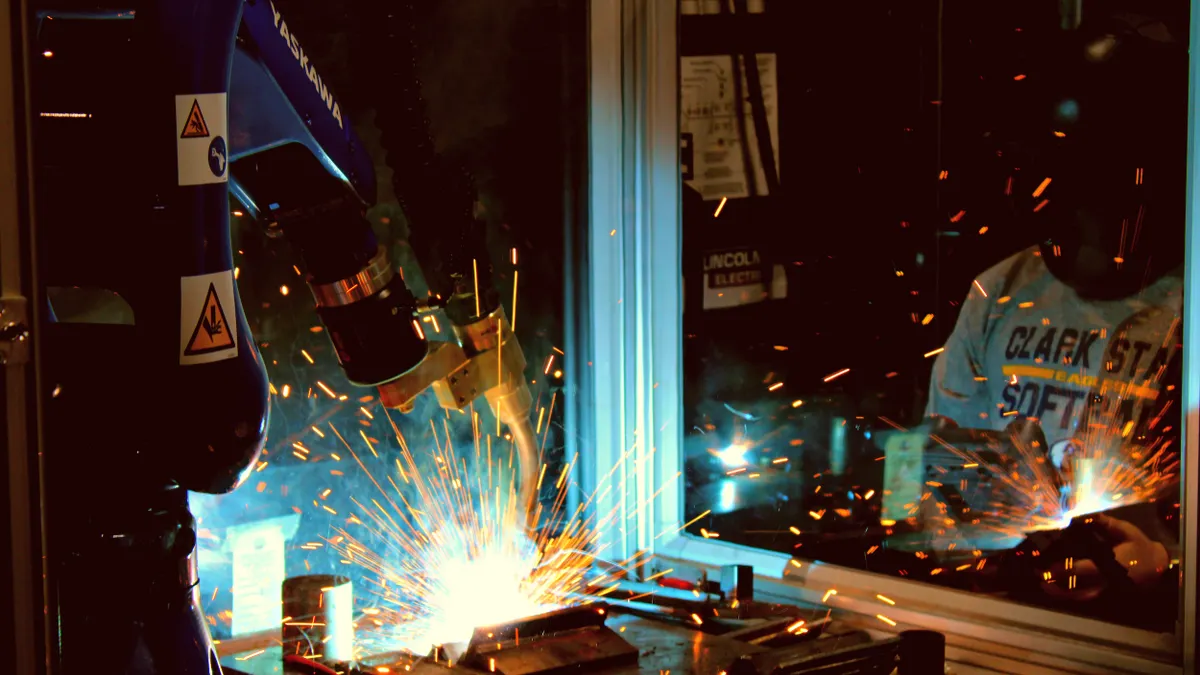

As automobiles become more technologically advanced, such as via software-defined features and autonomous driving systems, chipmakers are also seeing major growth in this key market.

Onsemi, a maker of sensors, microcontrollers and other semiconductor products, saw revenue for the automotive end-market increase to $787 million, up 7% from the previous quarter. This was driven by growth in Onsemi’s Americas, China and Japan regions, EVP Thad Trent said on an earnings call Nov. 3. Revenue for industrial and AI data center markets also increased sequentially.

“We have been positioning the company for a market recovery, and we believe we are well aligned to benefit as demand normalizes,” President and CEO Hassane El-Khoury said on the call.

Onsemi reported total Q3 revenue of nearly $1.6 billion, with the automotive market accounting for about half of the results. Net income increased to $255 million for the period, up 50% from the previous quarter. However, it was down 36.5% from a year ago.

Scottsdale, Arizona-based Onsemi has front-end and back-end manufacturing sites worldwide, including China, Canada and the Philippines, according to its latest annual report. In the U.S., the company has wafer fabs in New York, Oregon, Pennsylvania, Idaho and New Hampshire.

Meanwhile, other chipmakers are also optimistic about automotive. Currently, the sector accounts for about 25% of GlobalFoundries’ wafer revenue and is on track to near $1.5 billion in annual revenue for the company this year, Niels Anderskouv, president and COO said on a call. The company is expecting it to be a “multibillion-dollar business” by 2030, he said.

Diodes, a semiconductor firm based in Plano, Texas, that primarily manufactures and sells parts to Asia, saw automotive revenue grow 8.5% sequentially and 18.5% YoY, Emily Yang, SVP of Diode’s sales and marketing, said on a call Nov. 6. Despite the gains, she noted that the market is improving “slower than expected” as Diodes works through elevated inventory levels.

Tariffs spur operational flexibility and reshoring opportunities with customers

Amid tariff uncertainty, chipmakers are working to mitigate impacts to their revenues.

Diodes is “working aggressively” to leverage its flexible manufacturing sites and “move things around” to reduce impacts from U.S. imports, Yang said. However, the company’s tariff exposure is “relatively small” based on its operational footprint, she said.

Diodes reported $392.2 million in Q3 sales, up 12% over last year. About 78% of total sales accounted for customers in Asia and 10% for customers in North America, Yang said. The company posted net income of $14.3 million for the period, a 4% increase YoY.

“We always want to keep our flexibility to support customer[s] anywhere,” Diodes President and CEO Gary Yu said on the call. The company has wafer fabs in China, the U.K., Scotland, Taiwan and South Portland, Maine, according to its latest annual report.

On the other hand, GlobalFoundries has benefited from customer partners looking to reshore their technological capabilities to the U.S. The company recently agreed to manufacture Silicon Labs’ systems-on-chips at its Malta, New York, fab. Onsemi reported no material impacts from tariffs.

“As our customers increasingly seek to mitigate geopolitical risks and enhance their supply chain resilience, GF is helping them navigate trade complexities and optimize their sourcing decisions,” Breen said.