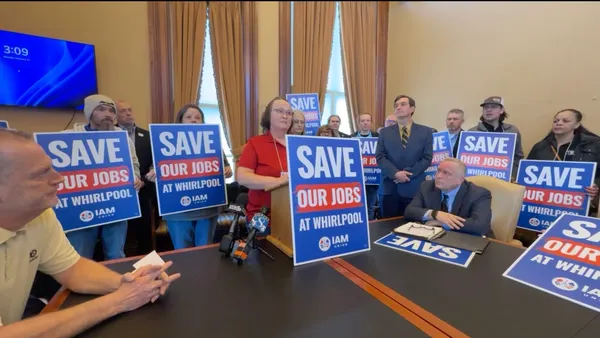

Imagine a frontline worker, Maria, clocking out after her sixth 12-hour shift in a row, missing her daughter’s recital because her schedule was posted just days ago. She’s exhausted, frustrated, and ready to quit. Maria’s story reflects a silent crisis costing manufacturers millions. A 2024 Deloitte study estimates replacing a single frontline worker costs up to $11,500, with turnover rates in manufacturing hitting 40% annually. The root cause? Outdated scheduling practices.

For the 50 million+ U.S. frontline workers powering factories, warehouses, and essential services, rigid schedules are a leading driver of burnout and turnover. A recent Gallup poll reveals 54% of employees would switch jobs for more schedule autonomy, while 64% crave shifts that align with their lives. These aren’t remote knowledge workers - they’re hourly employees whose input is rarely considered when shifts are set.

The Hidden Costs of Status Quo Scheduling

High turnover isn’t just a staffing headache; it’s an operational nightmare. Beyond the $11,500 replacement cost per worker, constant churn erodes tribal knowledge, increases safety incidents, and forces new hires into overtime before they’re ready. A 2024 SHRM report found that 20.8% of employees who had quit a job in the past year cite poor work-life balance, often tied to inflexible scheduling, as a top reason for voluntary turnover in frontline roles.

Yet many facilities still rely on paper schedules, Excel spreadsheets, or clunky enterprise systems unfit for dynamic shift environments. The result? Workers feel powerless, resentment builds, and retention suffers.

The Direct Financial Toll of Over/Understaffing

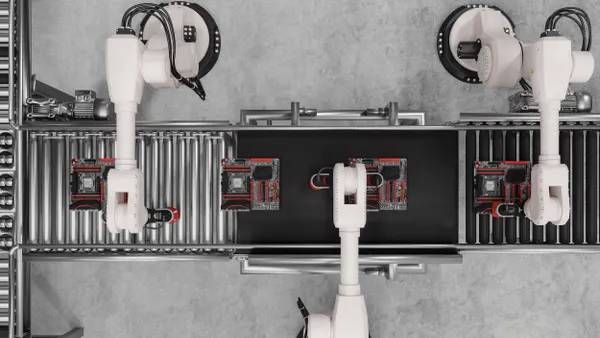

Scheduling inefficiencies don’t just hurt morale — they quietly drain budgets. Overstaffing adds millions in unnecessary labor spend each year, while understaffing leads to missed production targets, costly overtime, and safety risks. A Harvard Business Review analysis found that labor accounts for up to 70% of variable costs in manufacturing, meaning even small mismatches between labor supply and demand quickly erode margins.

Smarter scheduling practices that dynamically align headcount with production demand help manufacturers avoid these pitfalls. For example, demand-based scheduling can reduce overtime by 5–10%, translating into hundreds of thousands in savings annually at a mid-sized plant.

Redefining Flexibility for the Frontline

Smart manufacturers are turning scheduling into a retention superpower. Here’s how, based on insights from Indeavor, an innovative workforce management platform:

- Predictable Schedules: Posting shifts 2-4 weeks in advance reduces anxiety, helps workers plan, and reduces last-minute overtime premiums.

- Mobile Empowerment: Mobile apps let workers view, swap, or request shifts, boosting autonomy without burdening managers.

- Fair Work Distribution: Tools that track fatigue, hours worked, and time-off requests help prevent burnouts, lower grievance costs and decrease compliance risks.

- Skills-Based Alignment: Matching shifts to verified skills boosts engagement and prevents costly downtime.

One Midwest manufacturer adopted a demand-based scheduling tool tied to worker competencies and saw retention rise by 4.5% in under a year - saving $750,000 in labor and onboarding costs.

Scheduling as a Competitive Edge

The manufacturing industry is at a crossroads. As labor shortages intensify and operational demands grow, scheduling isn’t just a back-office task - it’s a strategic lever. Modern workforce management tools, powered by real-time data, are closing the gap between HR tech for desk jobs and the frontline.

“Don’t even try to sell retention as ROI” is outdated advice. Better scheduling is better retention, and every percentage point matters. Manufacturers that act now - by auditing their scheduling systems and adopting flexible, worker-centric tools - can cut turnover, boost productivity, and gain a competitive edge in a tight labor market.

Take Action: Evaluate your scheduling tools today. Are they empowering your workforce or driving them away? Visit Indeavor's workforce management platform and transform scheduling into a retention strategy.