When you think of additive manufacturing, or 3D printing, as it’s better known, you probably picture a plastic prototype on an engineer’s desk. A mockup or a proof of concept. Maybe even a hobbyist’s desktop machine, printing small runs of parts for testing.

But those days are long behind us.

Additive has evolved into a robust, reliable production tool. It’s delivering final parts in industries like aerospace, defense, energy, consumer electronics and more. The machines are faster, the materials are stronger, and the economics are compelling. In short – the technology has moved forward.

What hasn’t caught up is awareness of the full capabilities, the scalability, and the readiness of technology to tackle the most demanding of applications and scale.

Additive is already a production tool

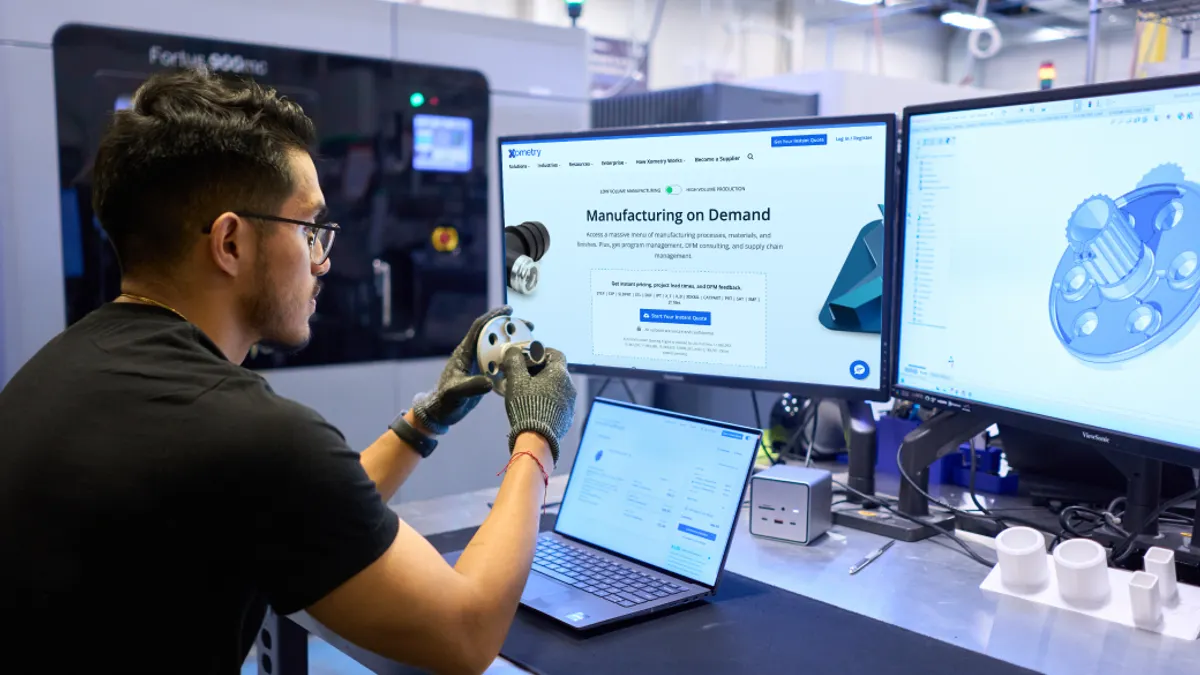

Across sectors, 3D printing is replacing traditional machining and molding for low-to-mid volume runs, particularly where speed, complexity, or customization make conventional methods too slow or expensive. One of Xometry’s manufacturing suppliers, for instance, prints thousands of customized enclosures for telecommunications which require various configurations based on the state or region of install. In traditional molding they would have to retool for every change, adding time and cost. Instead of retooling for every change, they simply update the design and print.

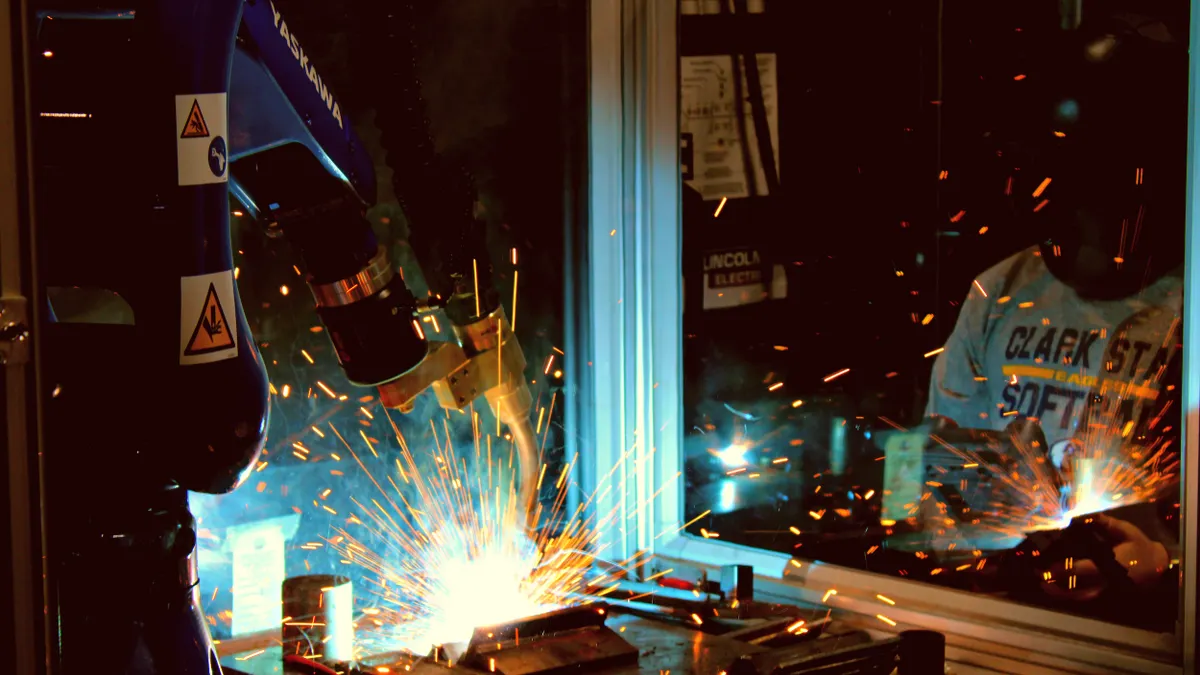

The same shift is happening in defense systems, autonomous vehicles and medical tools. In the drone sector, for example, manufacturers are ordering repeat batches of structural components: parts that need to withstand vibration, impact and changing environmental conditions. These are not concept pieces; they’re flight-ready hardware, built for deployment. In technology, for instance, additive is enabling the production of custom fixtures and tooling. In pharmaceuticals, additive parts are used to prevent evaporation and contamination in long-term experiments. Additive is bringing real solutions with real consequences. In each case, engineers aren’t just testing designs. They’re printing finished products, shipping them to active duty, installing them in clinical settings, or integrating them into next-gen vehicles already in development.

That kind of scalability wasn’t possible just a few years ago. Now, it’s routine. According to McKinsey, the industrialization of additive manufacturing could shift up to $250 billion in annual manufacturing value by 2030.

Materials are ready and affordable

Much of that $250 billion annual shift has been driven by advancements in materials. Additive now supports a wide range of high-performance options, including everything from UV-stable polymers to heat-resistant elastomers to production-grade metals. Engineers can specify mechanical, thermal, or environmental characteristics and choose from materials that meet those exact needs.

A new generation of SLA resins now deliver smooth finishes and durable performance at a fraction of the previous cost, up to 70% cheaper in some cases. These are the kinds of materials that once lived only in R&D labs. Today, they’re part of mainstream production workflows across electronics, consumer goods and healthcare.

Additive no longer means compromise. It means access and the ability to fabricate geometries that weren’t possible with traditional subtractive manufacturing methods.

Supply chains are driving demand

Just as important as materials is how additive fits into the broader manufacturing and supply chain landscape. With additive, companies can localize production, reduce inventory, and respond to changes in real time.

That’s why adoption is growing not only among global enterprises, but also across small and mid-sized manufacturers. Companies are using additive to mitigate risk, reduce complexity and support just-in-time manufacturing strategies that would be impossible with traditional methods.

From food production to industrial equipment to aerospace and automotive, additive is helping teams adapt faster with fewer constraints and less overhead.

Better awareness is the missing link

Still, a gap remains. Many engineering and procurement teams aren’t fully aware of what they can accomplish with additive manufacturing. They may have experience with filament-based desktop printers, but haven’t yet seen the depth of industrial 3D printing processes, or the range of certified materials and finishes available.

It’s not just hype, it is actually happening! But progress isn’t evenly distributed. The companies pulling ahead are also the ones closing the gap: equipping their teams with the knowledge to act, not just the access to machines.

The potential of additive manufacturing has already arrived. Now it’s a question of who’s ready to use it.