Breakthroughs in how robots can understand the real world, reason and plan actions are fueling the transition from research and development to commercial deployment across sectors, including manufacturing.

Earlier this year at CES in Las Vegas, Nvidia CEO and co-founder Jensen Huang said the “ChatGPT moment for physical AI is here,” marking an inflection point in the robotics space. Hyundai Motor Group also debuted its Atlas humanoid robot for production settings, with plans to gradually deploy them across its operations in the coming years.

In addition to collaborative applications and robotic arms, manufacturers are also increasingly using AI agents and sensor technologies to enhance their operations. However, as their systems become more digital, they also must take cybersecurity measures to prevent potential attacks.

Here are some of the AI and robotics trends to watch in 2026.

The physical AI hype is real, but the rollout will take some time

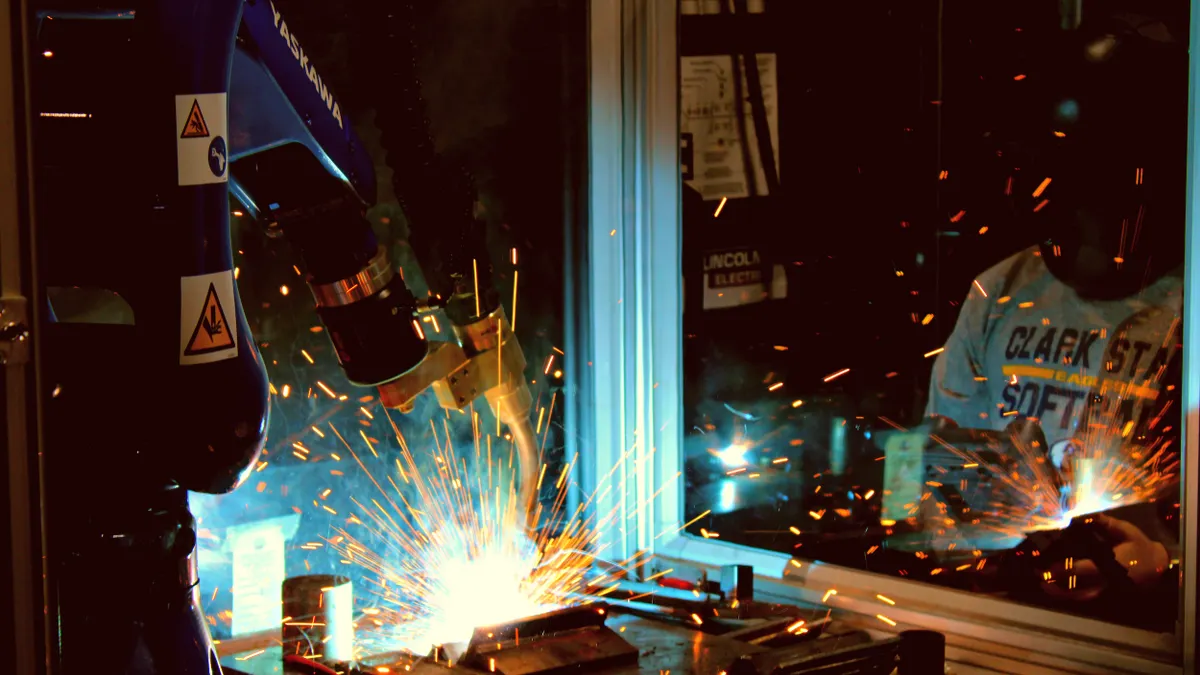

A number of manufacturers are already using physical AI, such as robotic arms and cobots, to fill labor shortages and handle repetitive tasks. But as carmakers like Audi and BMW pilot humanoids within their operations and ABB Group sells its robotics division to Softbank, the movement is set to go from niche to mainstream in 2026.

According to a recent Deloitte survey of more than 3,200 global business leaders, about 58% of participants indicated they were currently using physical AI to some extent in their operations for smart monitoring or production alongside humans. That number grew to 80% when asked about their plans over the next two years, with 15% using physical AI extensively and 3% fully integrating it.

“Everyone's getting really excited about it,” said Andy Lonsberry, CEO and co-founder of Path Robotics, a maker of autonomous welding systems. “Everybody wants to start prepping their facilities for this wave. And I think the adoption rate will be very, very fast, but I do think it's gonna be a bit of a slower rollout of making those capabilities go from demo to fully functional.”

Risks that result in unplanned downtime, which can cost companies millions of dollars in lost production, could outweigh the technology’s benefits and affect deployment in the near term. Path Robotics’ intelligent welding arms are designed for applications in the defense, utility, data center and heavy-equipment industries.

“Having a demo that works 70% of the time isn’t really going to cut it for manufacturing,” Lonsberry said. “It’s got to be [effective] like 99-plus percent of the time.”

One of the biggest challenges that robotics makers look to overcome is developing human-like dexterity and pressure control. With the convergence of vision, sensing, cobots and other robots alongside AI developments, Omdia analysts said in a recent outlook to expect more case studies of humans and more mobile robots working together in more flexible environments.

Cost-effective tools like AI agents and sensor technologies will surge

As manufacturers lay the groundwork for their digital transformations, they are turning more to AI agents and sensor technologies, also known as the Internet of Things, to autonomously monitor equipment, anticipate maintenance needs and manage supply chains.

Ed Nabrotzky, CEO of Dot Ai, a provider of tracking sensors and AI software, said the trend is accelerating, in part because the equipment is relatively inexpensive and the technology capabilities have improved in recent years.

Dot Ai’s battery-free labels connect to the internet and allow retailers, logistics companies and manufacturers to digitally track whatever they are attached to, including packages, equipment and other assets. The labels are based on technology developed by Wiliot and can measure things like temperature and light, allowing the viewer to know if a box has been opened, Nabrotzky said. They are about the size of index cards.

“You have a lot of assets trying to achieve an objective, and it used to be you could just ‘black box’ it, and so long as they got the job done, it was okay,” Nabrotzky said. “But we increasingly need to have full transparency of the process to know what’s happening.”

According to a Deloitte survey of 600 manufacturing executives, about 46% of respondents said they are using IoT solutions for enhanced visibility as they prepare their operations for increased automation. In November, Rockwell Automation announced plans to build its largest factory in Wisconsin. The facility will be equipped with advanced automation, robotics and digital systems, allowing the company to showcase its products to customers on-site.

AI agents, software systems such as large language models, are also becoming more ubiquitous across industries. A separate survey from Deloitte found that nearly 3 in 4 companies plan to deploy agentic AI within two years. IoT is playing a key role in accelerating the transition. Nabrotzky said after DotAi provides the labels, it provides supervised learning services to help customers implement agentic AI.

“Humans really can’t keep up very effectively,” he said. “And it’s very clear that algorithmic decision-making is going to bring tremendous efficiency to that market space and tremendous transparency for customers.”

More data means more cybersecurity risk

Not long ago, manufacturers were more immune to cyber threats due to the analog nature of their operations. As companies adopt more advanced technologies and work to understand the huge volumes of data they’re collecting, that is not the case anymore.

Manufacturing has been the most targeted industry for the last four years, according to IBM’s X-Force 2025 Threat Intelligence Index, with a high amount of ransomware attacks such as extortion and data theft. Many of the attacks are coming from hackers exploiting unprotected, outdated systems.

To counter these advanced threats, companies will have to adopt AI tools to enhance their cybersecurity measures. However, as companies navigate this integration they will need to strike a balance between automation and human judgment, according to the World Economic Forum’s 2026 Global Cybersecurity Outlook. While AI is good at repetitive, high-volume tasks, overreliance could create blind spots for hackers to exploit.

In August, Jaguar Land Rover suffered a cyberattack that halted production across its global operations for five weeks, resulting in $260 million in cyber-related costs and a 24% decline in revenue. In October, Japan-based beer maker Asahi also suspended operations following a ransomware attack that forced the company back to pen and paper.

About 59% of respondents from the manufacturing, supply chain and transportation sectors say they are adopting AI to augment cybersecurity capabilities, according to the World Economic Forum’s recent survey of 837 executives, academics and experts.

The number of participants assessing the security of AI tools has nearly doubled to 64% from the previous year, according to the survey. At the same time, 87% of them identified AI-related vulnerabilities as the fastest-growing cyber risk.

Looking ahead, Omdia analysts said 2026 marks a turning point for manufacturers, defined by integration, intelligence and industrial resilience. Cybersecurity and compliance readiness will become mandatory for global and regional market access, they added.