Al Ruiz is a senior professional recruiter at Actalent, a global engineering services and talent solutions company. Opinions are the author’s own.

As manufacturers across the country race to keep up with nearshoring demands and technological advancements, a lack of engineering talent is complicating the equation.

A third of engineering roles already go unfilled each year, a problem that experts project could continue through, or even beyond, the end of the decade. The industrial equipment industry is especially affected, with more than one in five machinery manufacturers running below full capacity during Q2 due to insufficient labor, according to the U.S. Census Bureau’s latest Quarterly Survey of Plant Capacity Utilization.

As a recruiter, I’ve seen firsthand the struggles to find experienced engineers. Thankfully, there are several best practices that industrial equipment manufacturers can follow to attract and retain the talent they need to stay ahead.

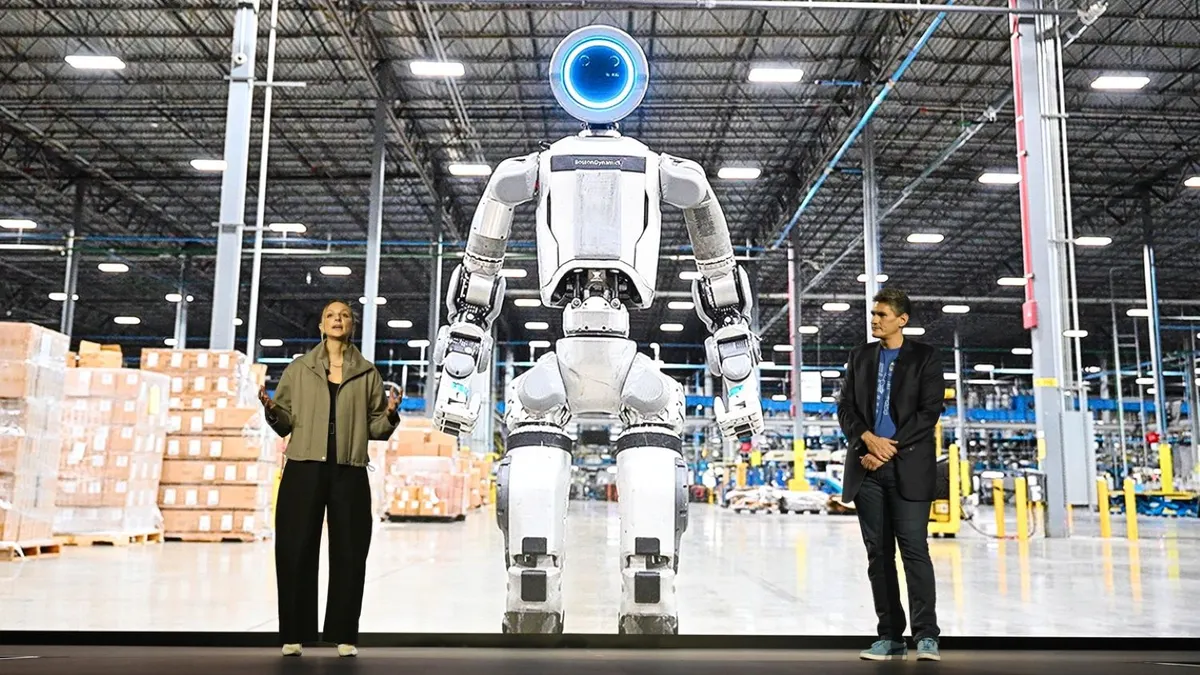

Automation’s double-edged sword

Industrial equipment manufacturers are increasingly turning to automation to reduce costs and adapt to changing workforce trends. But this means they are more and more dependent on the specialized engineers capable of installing and maintaining these systems: namely, programmable logic controls engineers and designers.

There are three key factors currently widening the talent gap:

- Demand: As industrial equipment companies look to automation, there simply aren’t enough skilled engineers to fill the number of available roles, creating intense competition for talent.

- Technological gaps: On the design side, companies use a variety of expensive computer-aided design software, with individual seats on a license often costing tens of thousands of dollars. As a result, companies often use outdated programs, and designers familiar with such software may be hard to find. It’s an unusual reversal of the typical skills gap. Instead of workers struggling to keep up with new developments, they need to be proficient in old-school systems.

- Work-life balance: PLC engineers usually spend 70-90% of their time traveling to factories spread out across the country, even working 12-hour shifts over weekends and holidays to get the machinery operational by Monday morning. This makes it hard to attract and retain employees, since qualified engineers often transition into plant control maintenance jobs that offer better schedules and more stability.

The steep demands of these jobs mean turnover is common. Yet the consequent loss of institutional knowledge only compounds the shortage, leaving employers scrambling to backfill critical positions.

Strategies for industrial equipment engineers

In the short term, employers in the industrial equipment space will continue to struggle to hire and keep highly skilled PLC engineers and designers.

Rather than holding out for the perfect candidate, manufacturers should look for employees who can learn on the job. After all, under current conditions, waiting to hire an experienced engineer could take just as long, or longer, than training an entry-level hire.

Fortunately, early- or mid-career engineers with associate’s degrees, or even those who don’t have a degree and are looking to make a late-in-life career change, can develop the necessary skills through structured training programs, apprenticeships or mentorship from a senior engineer.

Partnerships with local community colleges and trade schools can help establish both formal training courses and a talent pipeline to address the shortage in the long term.

In Michigan, for example, some colleges have taken note of the surging demand for these skillsets and the employment opportunities they offer graduates. They’ve created technician programs that include key certifications and hands-on training for people at differing experience levels, from entry-level certificates to master’s degrees.

In the near term, manufacturers can also explore staffing firms and contract engineers to fill critical gaps. Hiring experienced engineers to meet immediate needs can take pressure off trainees and address workload challenges among existing employees.

Creating conditions for long-term success

Employers should also address some of the cultural and systemic barriers to retaining engineers.

Experimenting with flexible schedules, flying employees home when possible, or pursuing sabbatical-style work cycles could help improve work-life balance for these key roles and prevent burnout down the line.

For example, I once worked with a controls engineer who had a passion for traveling. He’d frequently take a seven- or nine-month contract with a company, then spend two to three months afterward traveling around the country. The flexibility was a perfect fit for his personal goals, which made the job sustainable for him while still meeting the needs of his employers.

Additionally, if outdated CAD systems are a barrier, companies should consider investing in the latest technologies that early-career designers are more likely to know. While this will come with substantial costs, it may be worth the competitive advantage having a skilled workforce brings.

Adapting today, building resilience for tomorrow

Ultimately, solving the labor challenge in the industrial equipment sector will require more than incremental fixes. Companies must view workforce development not as a short-term expense but as a long-term investment.

Training programs, educational partnerships and cultural reforms all take time and resources, but they are essential for sustaining growth in an automation-driven world. The shortage of skilled labor is not a problem that will resolve on its own. It is a structural issue that requires planning, creativity and commitment today.

The industrial equipment sector’s outlook is promising, but only if the industry can ensure that the right people are behind the machines.