CHICAGO — It’s been a wild year with tariffs and other trade impacts on manufacturers in 2025.

But what’s in store for 2026? Jennifer Clement, client relationship leader of investment advising firm Clifton, Larson, Allen, offered insights and strategic guidance on trends the company is currently seeing in the marketplace at the Women in Manufacturing Summit on Oct. 14.

Clement discussed some of the economic drivers for next year that will provide manufacturers with opportunities to stay competitive.

Cashing in manufacturing tax coupons

Manufacturers have been living in a world of uncertainty, including on the tax front, Clement said.

Up until the One Big Beautiful Bill Act became law on July 4, manufacturers had high interest rates, she added. Research and development and purchased equipment couldn’t immediately be expensed, which led to manufacturers paying more taxes for several years.

“It was the perfect storm,” Clement said. The OBBBA passing provides “significant opportunities to help alleviate this pain.”

Manufacturing-related highlights from the tax law include larger interest deductions on debt, “a big deal” if companies are doing any merger and acquisition work and financing deals with interest, she said.

The new law also permanently restores expensing for research and development and capital equipment purchases. Regarding the R&D tax credit, many manufacturers aren’t taking advantage of the incentive due to misconceptions, Clement said.

“Most people think of R&D like lab coats and test files,” she said. “The definition of R&D is much bigger than that.”

If a company does process workflow implementation on the shop floor or installs or debugs machinery, or rearranges a production line, these fall under the R&D category. These items are to be considered for year-end tax planning, Clement said.

“If you’ve been amortizing R&D, which we’ve painfully been doing for the last few years, and you have unused amortization, you got a coupon,” the CLA client relationship leader said. “You can use it either this year or you can use it next year, so super important from a 2025-year-end planning perspective to figure out when do you want to cash in your coupon.”

If manufacturers are thinking about bringing their operations to the United States, they should seek state tax incentives, she added. Lastly, manufacturers should also take advantage of the workforce opportunity tax credit, which Clement adds that companies are not taking advantage of as well. The WOTC allows companies to take a $2,500 to $9,600 deduction on hiring people under four categories: veterans, people with disabilities, formerly incarcerated, and low-income communities in certain zip codes.

However, the WOTC is authorized until Dec. 31, according to the Department of Labor’s website.

Tariffs: ‘Shock to the business’

While the Supreme Court will hear oral arguments on whether to uphold President Donald Trump’s tariff powers on Nov. 5, it doesn’t mean the duties will disappear, Clement said.

For one, tariffs are used to offset the national debt. Furthermore, when Trump imposed tariffs in 2018, he used section 203 of the International Emergency Economic Powers Act to place the levies, which is what will be debated in front of the Supreme Court. The law gives the president the power to use certain authorities relating to commerce with foreign nations, determining if the countries are an existing “unusual and extraordinary” threat against the U.S.

If the Supreme Court throws out the case, companies can apply for refunds, Clement added. She urges manufacturers to document any duties they paid under the IEEPA to receive any refunds. The court could also keep some tariffs in place and throw others out.

“We’re not sure, but the key is documentation of what you have paid as an organization under IEEPA, which is super important right now, in case we do have some form of rebate opportunity,” Clement said.

Using saved tax money to invest in technology

The new tax law could offer opportunities to invest in AI-assisted technology that can help a manufacturer’s business.

Clement referenced Rockwell Automation’s 10th Annual State of Smart Manufacturing Report, 95% of manufacturing leaders have invested or plan to invest in artificial intelligence/machine learning, Gen AI, or causal AI in the next five years.

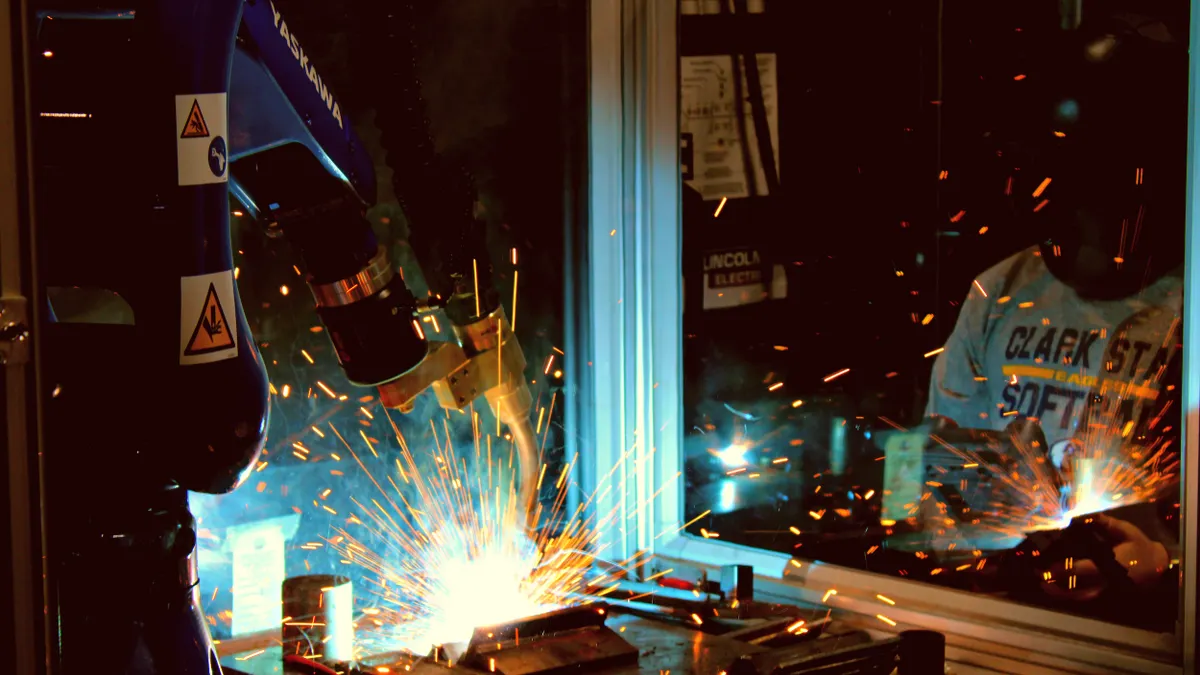

The report also found that 50% of manufacturers spent capital on quality control, 42% invested in process optimization, and 37% contributed funds to robotics, which are all AI-related, Clement added.

To get started, ensure employees are using AI-assisted tools behind a firewall so the company’s data is not released to the internet, Clement said.

Manufacturers can set up an AI crawl in their enterprise resource planning system, freeing up workers for other duties, she said.

“In this market, labor is a fixed cost,” Clement said. “We’re not laying off people related to AI in manufacturing. We are freeing up those resources to do other things, because we keep them, we reskill them, we upskill them, versus moving them around in the organization.”

It’s also key to create a roadmap, as companies have different types of opportunities to use and leverage AI.

“As you’re building that AI role, think about the top business problems that you have, retirements, transition, maintenance, reactive versus proactive. Let's start there in manufacturing, and build your roadmap based on where you're seeing pinch points.”