U.S. sustainability policy may have shifted, but some manufacturers are still finding a faster path to climate, governance and workforce gains by investing in domestic production.

The reshoring wave has triggered staggering levels of investment: Apple has pledged more than $500 billion toward U.S. operations over the next four years, and Johnson & Johnson plans to channel $55 billion into domestic production through 2029, among many others.

With new tariffs reshaping production costs, manufacturers are reassessing whether reshoring can deliver not only resilience but measurable sustainability gains. From a supply chain perspective the shift is logical, especially after the lessons of 2020.

"Covid was an eye-opener. Backlogs, port closures, and labor inability caused us to have business disruptions," said Mohit Ahuja, director of operations strategy and business transformation at Caterpillar. "Today's U.S. policy is causing us to put reshoring on the front burner, and balance sustainability with optimizing the cost of production."

Supply chain disruptions, geopolitical risks and stakeholder scrutiny have contributed to driving reshoring.

"70% of our dependency came from a single region. Through our optimization programs, we’re now looking at how we could reduce single country risk," said Ahuja.

Offshoring decisions may be financially driven. According to the 2025 Reshoring Survey Report by Regions Recruiting, a talent acquisition firm, 69% of survey participants cite cost as a reason for offshoring.

The survey found that long-term company sustainability and short- to medium-term company profitability were the leading factors when deciding whether to reshore. Environmental, social and governance factors ranked as a lower consideration among respondents.

Mitigating supply chain and geographic risks are just two opportunities companies consider for bringing operations back to the U.S. Domestic operations also offer greater visibility into worker safety, procurement practices and regulatory compliance.

"Success metrics could include reducing scope 3 emissions, waste and water, and energy management. Other areas are job safety and job creation, as well as sourcing and traceability," said Katie Martin, director of sustainability and innovation at Avetta, a supply chain risk management platform.

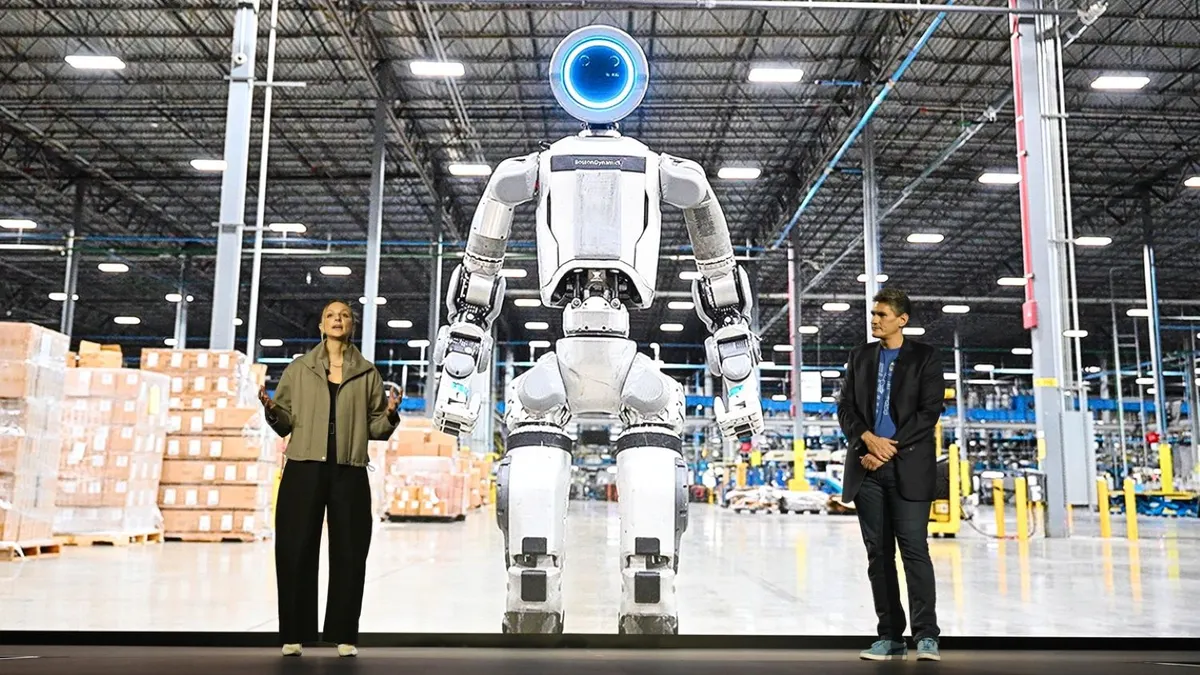

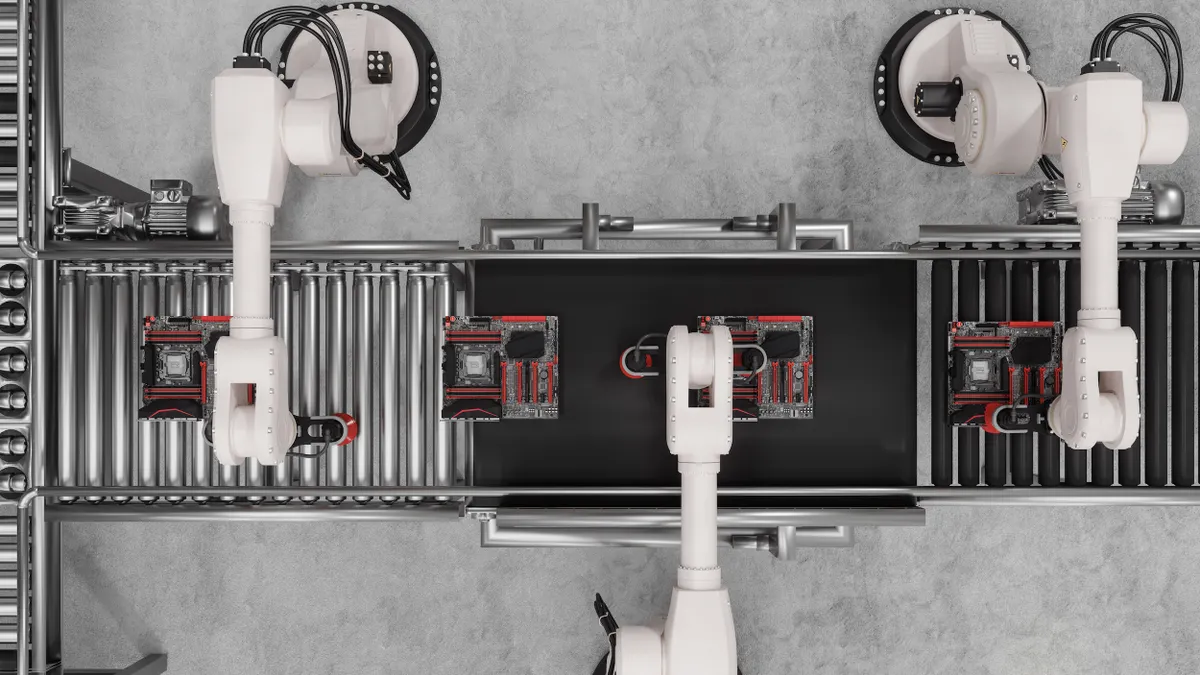

How manufacturing innovation enables sustainability

Reshoring often drives advanced automation to counter higher U.S. labor costs and boost efficiency beyond offshore levels.

"Production is dependent on managing energy, making sure utilities are not wasted. With that, AI has been an enabler for us to have a much more efficient output," said Ahuja.

These technological innovations connect directly to sustainability outcomes: enhanced energy efficiency, improved material utilization and reduced waste and downtime.

However, growth-generating advantages may come at a cost.

"When our clients consider minimizing their sustainability impact by shortening the travel cycle or readjusting geographically, what we see from an emissions standpoint is a focus on absolute emissions instead of displaced emissions. What that’s doing is moving the cups around instead of reducing the size of the cups," said Martin.

"This is specifically impactful in U.S. environments where we have infrastructure challenges, renewable energy access, and stress on existing water systems, where you could actually be increasing your overall and absolute emissions."

Martin said this means companies should take an integrated approach in which they think about a range of factors such as process efficiencies, changing packaging materials and assessing core manufacturing aspects. She also suggested companies think about decisions that reduce overall intensity per unit, versus just shortening geographic distances, because this “may at best leave you at a net neutral outcome, both on cost and sustainability.”

Another key consideration is rigorous measurement.

"Formulate the baseline of before and after, so your baseline is from when you started the reshoring. Understand what is increasing, what is decreasing, and then always quantify that with the dollars that are corresponding to that," said Shivani Rajpal, CEO of Earth Academy, a sustainability education firm.

Companies must also be patient.

"Like in any sustainability topic, you cannot see the results tomorrow," Rajpal noted, pointing to the need to evaluate impacts across the short- to long-term horizons, spanning from one year to 10-plus years.

Balancing costs and risk reduction

While higher domestic labor costs remain a consideration, they must be weighed against reduced logistics expenses, lower inventory costs and decreased disruption risks.

Caterpillar's $725 million expansion of its Lafayette, Indiana, facility illustrates a strategic approach by prioritizing workforce development. Despite maintaining an offshore presence and examining risks from recent tariffs, Caterpillar is pivoting toward reshoring. The company has committed $5 million to upskilling initiatives in Indiana as part of a broader $100 million, five-year workforce pledge.

Human capital is central to sustainability. Experts say firms with a strong U.S. supplier base can better oversee worker safety, equity and treatment, improving both company value and sustainability performance.

"You have to think about your social and labor practices and how they may result in a higher score with rating agencies. With that, the company's reputation is enhanced. This may lead to an increase in customers, as well as lower risk of regulatory fines. These all lead back to financial measurement," Rajpal said.

Reshoring without proper strategy, however, carries significant risks.

Otis' 2012 relocation of elevator manufacturing from Mexico to South Carolina exemplifies these challenges. The move faltered due to simultaneous initiatives including streamlining the product line, implementing a new computer system and struggling to build an adequately trained workforce. This cost parent company United Technologies $60 million and created significant order backlogs.

More recently, Intel's Ohio semiconductor plant had similar challenges in domestic projects, with completion delayed from 2025 to 2030. The project has struggled with difficulty securing customers and workforce shortfalls, employing only 800 workers as of early 2025, despite plans for 7,000.

"Reshoring is not simply about investing over the near term. It sometimes takes decades to make these investments. Then you must identify which [supply chain] links are viable in a reshoring or nearshoring situation," said Caldwell Hart, principal for procurement and supply chain management at Avetta.

Hart outlined three critical steps: prepare for long-term investment with clear cost recovery plans, identify which supply chain links remain viable under reshoring scenarios, and ensure the ability to meet earnings, margins and other stakeholder requirements.

Companies must also consider market access trade-offs, Hart said, noting that abandoning overseas facilities may mean forfeiting revenue opportunities in rapidly growing international markets.

"Being in another country may not be just to build parts in Asia to bring back to the U.S. — it may be to have a presence there because you want to penetrate markets to sell your goods and products into.”