Across the U.S., manufacturing leaders are embracing Industry 4.0, investing in automation, data integration and smart systems that promise to drive efficiency and reliability. Yet many pilot projects stall before delivering measurable ROI. According to an Accenture study of 600 manufacturers, the average digital maturity score sits at just 39 out of 100, suggesting that while many have moved past the proof-of-concept stage, most are still struggling to scale.

At Belden, we call this problem “scale fail.” It’s the invisible barrier between a successful pilot and a fully realized, connected operation.

The common culprits of scale fail

From “shadow IT” to outdated equipment and scattered data, manufacturers often face systemic hurdles. Legacy systems are patched together with short-term fixes. Data flows are inconsistent and siloed. And pilots often focus on immediate pain points rather than long-term transformation.

Perhaps most importantly, the people behind the machines—operators, engineers and decision-makers—are frequently left out of the process. Without buy-in across every level of the organization, even the smartest pilot can stall out.

Rooted in America: modern manufacturing that scales

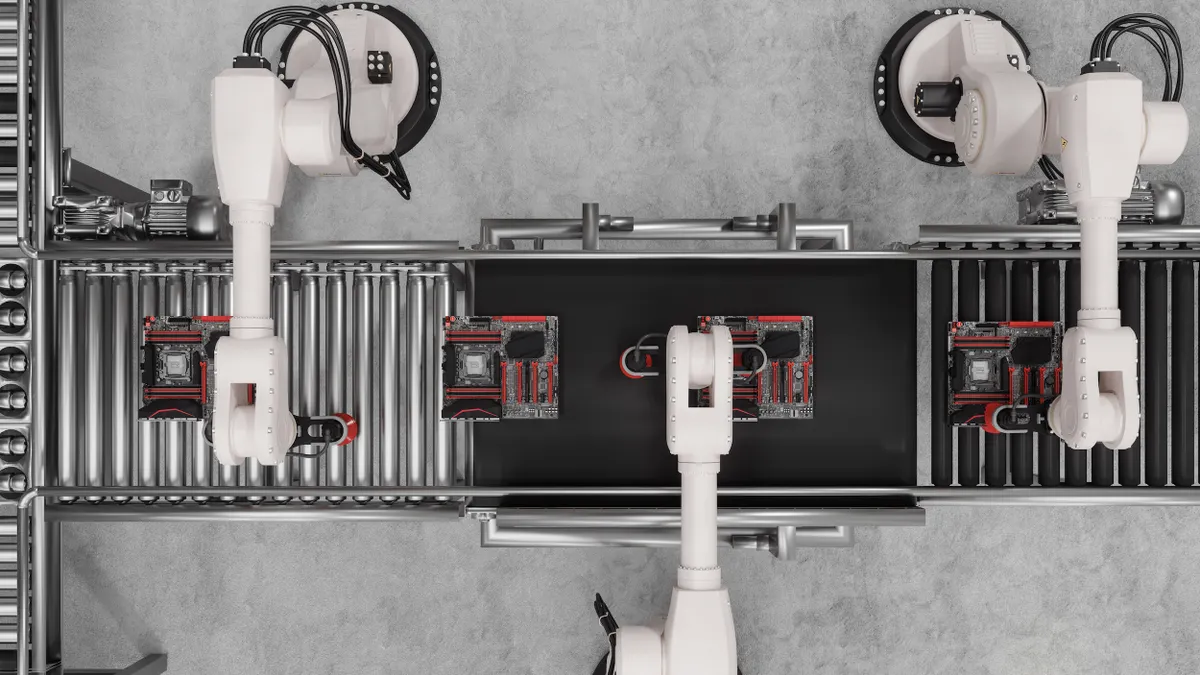

Belden knows firsthand what it takes to overcome these challenges. At our Richmond, Indiana facility, one of the company’s cornerstone U.S. manufacturing sites, decades-old equipment and disconnected systems once led to unplanned downtime and inefficiencies. By combining Belden’s own networking infrastructure with AWS cloud and edge computing, the facility gained real-time visibility into operations and predictive maintenance capabilities.

The result: an 18% increase in Overall Equipment Effectiveness (OEE) and an $833,000 annual reduction in costs.

This transformation wasn’t just a tech upgrade. It was a demonstration of what Rooted in America truly means. It’s proof that American manufacturing can lead the global shift to smart, connected production when backed by innovation, reliability and the right partners.

Four strategies to build scalable success

Belden’s Industry 4.0 experts have identified four key strategies to help manufacturers avoid scale fail:

- Unlock insights in data: Ensure reliable access to OT data, integrate IT and OT and contextualize insights from the plant floor to the boardroom.

- Take a comprehensive approach: Design pilots with scalability in mind, using diagnostic tools to uncover root causes, not just symptoms.

- Make the human connection: Balance people, process and technology to secure buy-in across your workforce.

- Try a platform approach: Build a flexible foundation that supports multiple use cases and evolves as your operations grow.

When these strategies work together, they create the conditions for sustainable growth and position American manufacturers to stay competitive for the long term.

From proof of concept to proof of performance

Smart manufacturing is not about testing technology for technology’s sake. It’s about scaling success stories that prove measurable results that can be replicated from one plant to another, across an entire organization.

Belden’s Rooted in America initiative reflects that same philosophy: innovation built on legacy, designed to power what’s next. From factories to data centers, Belden is helping manufacturers strengthen domestic infrastructure, minimize downtime and unlock the full potential of Industry 4.0.

Ready to scale your next pilot?

Discover how Belden helps manufacturers connect the dots between people, processes and technology while keeping production moving through anything.

👉 Explore the Rooted in America story and access our Industry 4.0 resources here to start building your next scalable success.