Artificial intelligence (AI) is revolutionizing the manufacturing sector, offering new avenues to enhance efficiency, optimize processes, and drive innovation. However, the journey to successful AI implementation is complex, requiring a strategic approach that aligns technology with business objectives. This article delves into the AI maturity curve in manufacturing, providing insights on how organizations can effectively navigate this transformative journey.

Understanding the AI Maturity Curve: The AI maturity curve outlines the stages of AI adoption within an organization, each representing a different level of integration and sophistication. For a comprehensive understanding of these stages, refer to the full AI Maturity Study report.

Stage 1: Awareness and Experimentation: At this stage, manufacturers explore AI's potential through pilot projects, gaining insights into its capabilities. Common applications include predictive maintenance and quality control, where AI tools are tested for their effectiveness.

Stage 2: Focused Implementation: Organizations begin to identify specific use cases where AI can deliver substantial value. This involves implementing AI solutions in targeted areas such as supply chain optimization and production planning, where tangible benefits can be realized.

Stage 3: Strategic Adoption: AI becomes a core component of business processes and decision-making. Manufacturers leverage AI to automate complex tasks, enhance real-time visibility, and improve overall operational efficiency, integrating AI into the fabric of their operations.

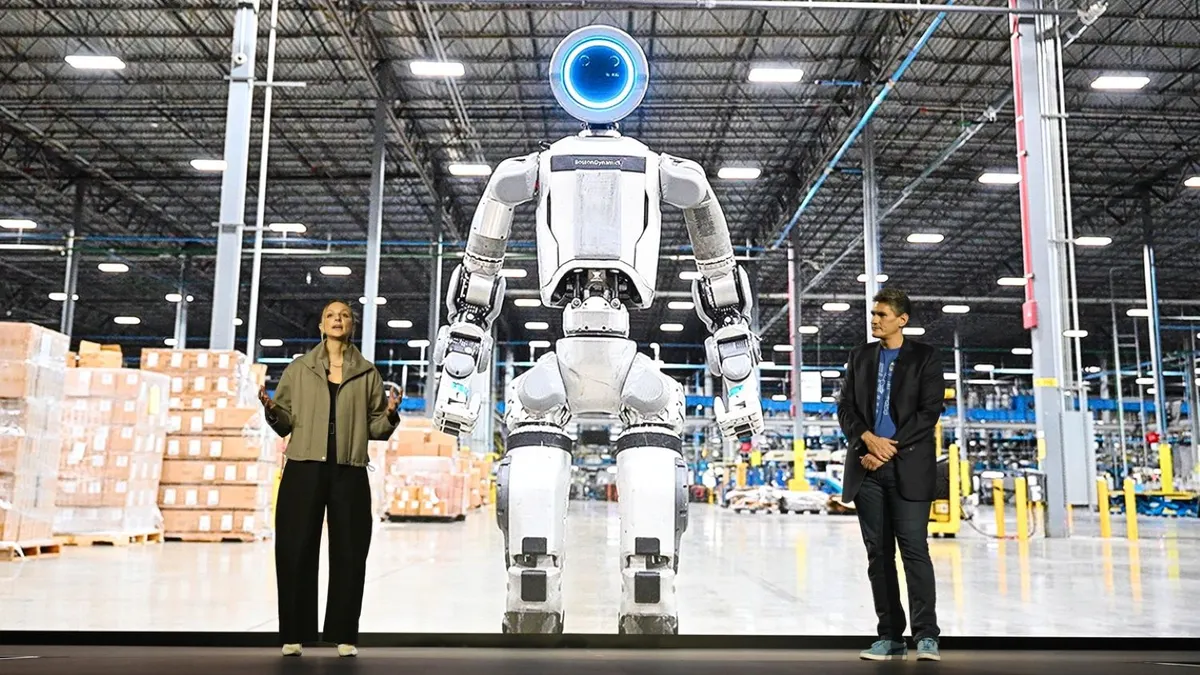

Stage 4: Transformation and Innovation: AI drives fundamental changes in business models, fostering a culture of innovation. Manufacturers use AI to develop new products and services, personalize customer experiences, and gain a competitive edge in the market.

Key Considerations for AI Implementation in Manufacturing

Data Strategy: AI algorithms thrive on high-quality data. Manufacturers must establish a robust data strategy encompassing data collection, storage, processing, and governance to ensure AI systems function optimally.

Skills and Talent: Implementing and managing AI solutions require specialized skills. Organizations should invest in training programs to develop internal AI expertise or collaborate with external experts to bridge skill gaps.

Integration and Interoperability: Seamless integration of AI systems with existing IT infrastructure and operational technologies (OT) is crucial. Manufacturers should prioritize solutions that support open standards and interoperability to ensure smooth operations.

Security and Compliance: AI systems can introduce new security risks. Manufacturers need to implement robust security measures to protect sensitive data and ensure compliance with industry regulations.

Conclusion: Navigating the AI maturity curve is a strategic journey that requires careful planning and execution. By understanding the stages of AI adoption and addressing key considerations, manufacturers can harness the full potential of AI to transform their operations, drive innovation, and maintain a competitive edge in the ever-evolving market landscape. Learn more about leveraging AI Agents for improved workflows on ServiceNow's AI Agent page.