If you haven’t been living under a rock, you know that we’re currently at a crucial time in American manufacturing. We’ve already written articles on the next age of manufacturing and how tariffs will spur that era onwards. In both cases, we emphasized innovation as a key factor for continuing success. But we know that just saying “be more innovative!” isn’t the most helpful advice. And unfortunately, we can’t prescribe exactly what you should do: the breakthrough innovation for each and every company will be different.

However, through studying manufacturers on the forefront of innovation, we’ve identified three major levels at which innovation happens. Thinking about what you’re currently doing and what pain points you experience on each level will open the door for innovative ideas.

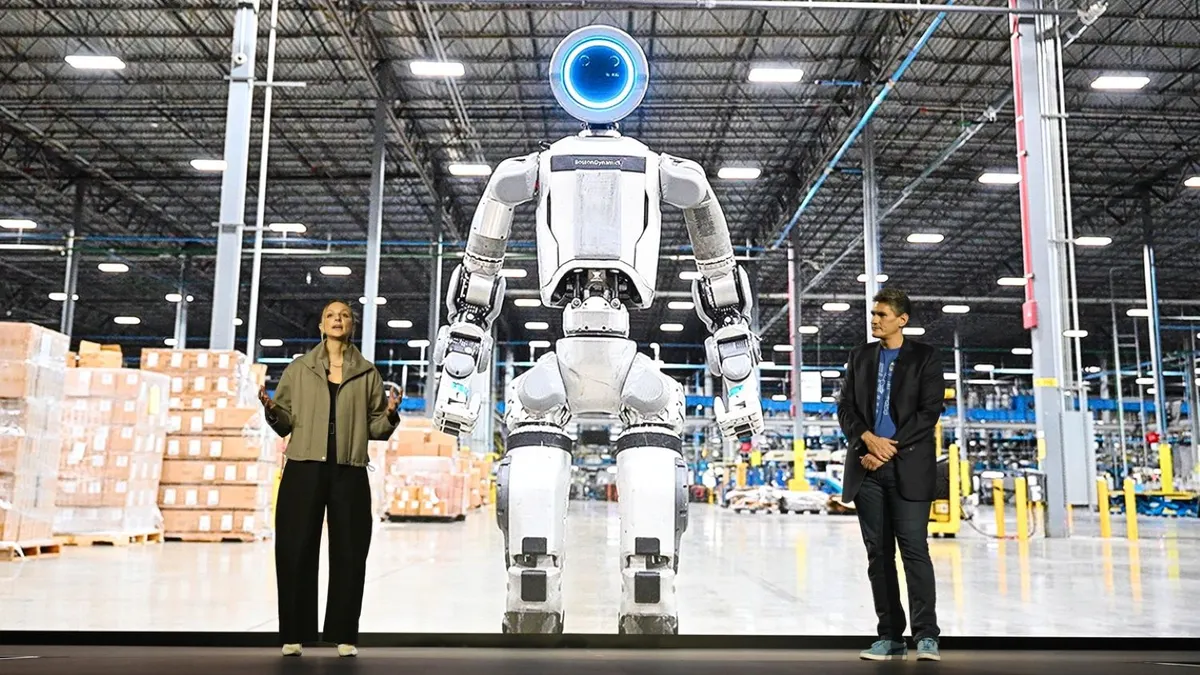

First is innovation in the manufacturing process itself, happening on the factory floor. There are a few gigantic revolutions on the horizon here. Perhaps the largest, and certainly the most “sci-fi”, is the rise of humanoid robots, able to work dynamically and intelligently on the shop floor without rest or error. Breakthroughs in robotics, thinking AI models, and machine vision are bringing multifunctional robots into reality, promising revolutionary increases in productivity and output diversity. Combined with new additive manufacturing (e.g. 3D printing) capabilities, the shop floors of 2030 may be nearly unrecognizable.

At first, these types of innovations are extremely costly investments, available only to the largest manufacturers. But the situation literally advances every day, with new opportunities emerging that you ought to consider. That brings us to our second level of innovation: innovation at the strategic level.

We’ve talked at length about the turbulence American manufacturers will continue to face, and how being flexible, agile, and knowledgeable is the only way to stay afloat. As challenges and opportunities continue to emerge day by day, you need to seek out and implement innovative strategies for your budgeting, sourcing, tool adoption, labour distribution, and more.

Okay, so our advice so far: seize new technological innovations as they become feasible, and constantly innovate your strategy as new information comes in. Nothing mindblowing, right? But what we’ve found is that there’s a middle level that many manufacturers neglect. Despite the information process containing many of the most obsolete areas of their business, areas that are most needing innovation, we find that many leaders have a blind spot for this third level of innovation: the level of information.

Every innovative decision we’ve referred to, from “what’s our costs and gains if we upgrade this production line machine?” to “will it be cheaper in 5 years to start producing this part in-house than buying it from overseas?”, requires a ton of data to answer. And when that data is difficult to get, it means that by the time you make the decision, you’ve already missed the biggest benefits of implementation, or even missed the boat entirely.

If data is scattered across random pdfs and spreadsheets, or locked in emails, filing cabinets, and the brains of senior employees, or labelled only with inscrutable ID numbers, it will be very difficult to find. This is the unfortunate reality of many manufacturers: their information practices haven’t been innovated since the early 2000s. Even otherwise innovative and extremely established companies like Subaru used to struggle with simple, frequent inquiries taking a week or more to answer.

Fortunately, this stagnation means there’s plenty of low-hanging fruit in the information level. CADDi, the AI data platform for manufacturing, worked with Subaru to get those week-long inquiries down to a few minutes, with even new employees finding what they needed without help. By making data easy to access, with intuitive searching and AI-empowered connections and analysis, hundreds of hours of tedious work were eliminated across the organization. Check out our case study with them to see how we revolutionized their information access, and through it, everything else.

Simply put, whether it’s on the shop floor or in the executive boardroom, innovation is the necessary solution to big challenges. And innovation always requires information, the data you need to answer the questions that lead to big decisions. With CADDi, you can innovate your decades-old data processes themselves, unlocking innovation across your entire organization.