In a high-pressure production environment, where timing and accuracy are critical, even small inefficiencies in warehouse operations can snowball into significant business disruptions. If you’re one of the many manufacturing organizations that deal with missing stock, miscounts, or frustrated customers due to incorrect inventory data, you’re not alone.

Keeping inventory accurate in a warehouse can feel like a never-ending challenge, especially when operations scale up and order volumes increase. Here are five key strategies that help warehouses maintain 99.9% inventory accuracy, minimize human error, and make stock tracking seamless.

1. Implement real-time inventory tracking

Let’s start with the most powerful change you can make: real-time inventory tracking. How to achieve this:

- Automated stock-scanning robots: If you had a robot scanning your shelves daily, how much more confident would you feel about your inventory data?

- Barcode tracking: Barcode scanners improve visibility, making stock movement easier to track. They also reduce picking errors and speed up order fulfilment.

- Cloud-based inventory management: Using a system that updates in real-time means that every department—warehouse, logistics, sales—sees the same up-to-date stock levels, preventing miscommunications.

2. Conduct regular and automated cycle counts

Relying on a once-a-year full inventory audit is risky. By the time errors are found, they’ve likely caused weeks or months of operational issues. Best practices for cycle counting:

- ABC analysis: Not all stock is equal. Prioritize high-value and fast-moving items (Category A) for frequent cycle counts, while lower-priority stock (Categories B & C) can be counted less often.

- Automated cycle counting: Manually counting stock is time-consuming and prone to mistakes. Using robots or AI-driven inventory checks ensures accurate, unbiased results without human error.

- Random spot checks: High-risk stock locations, such as return areas or frequently accessed shelves, should be checked more often to prevent accumulating errors.

3. Improve warehouse organization and layout

Even with the best tracking systems, a disorganized warehouse makes mistakes more likely. How to improve organization:

- Slotting strategy: Place frequently picked items in easy-to-reach locations, while low-turnover items can be stored in less accessible areas.

- Clear signage and labelling: Every aisle, bin, and shelf should be clearly labelled. Misplaced stock is often the result of unclear location markers.

- Fixed vs. dynamic storage: Some warehouses benefit from fixed storage locations, where each SKU has a designated place. Others use AI-driven dynamic storage, where stock is placed based on movement patterns.

4. Minimize inventory handling errors with standardized processes

Even with advanced systems in place, human errors in stock handling remain one of the biggest causes of inventory discrepancies. How to reduce handling mistakes:

- Enforce a ‘Scan Everything’ policy: Every stock movement (inbound, outbound, and internal transfers) should be scanned and recorded in real-time.

- Introduce error-proofing (Poka-Yoke) techniques: Mistake-proofing methods like barcode scanning validation, pick-to-light systems, and automated alerts

- Use visual cues for stock accuracy: Color-coded shelf labels, digital displays, and AI-powered vision systems can make it easier to identify stock location errors at a glance.

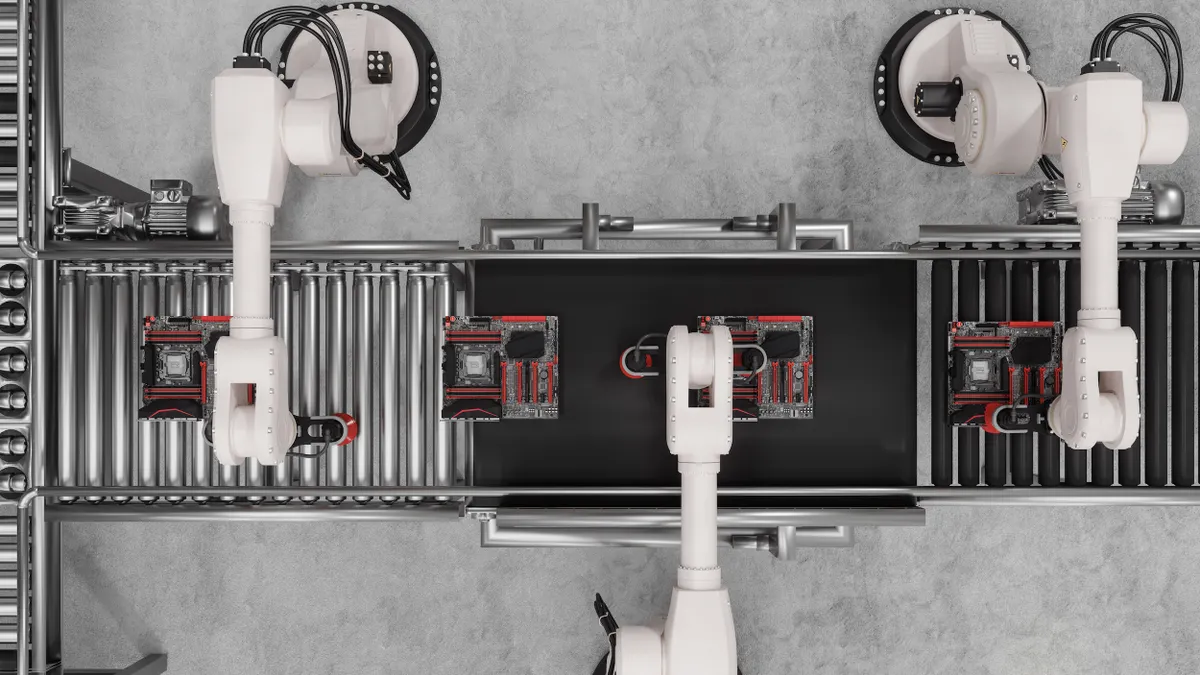

5. Reduce human errors with robotics and automation

Even the best employees make mistakes, especially when pressure is high and order volumes surge. Key technologies to consider:

- Autonomous Mobile Robots (AMRs): Robots can autonomously scan and validate stock, ensuring discrepancies are caught before they impact order fulfilment.

- AI-powered vision systems with robots: AI-based cameras detect misplaced stock and flag errors instantly.

- Automated order picking: Pick-and-place robotic systems reduce mispicks, increasing accuracy and fulfilment speed.

Final thoughts: Accuracy = profitability

Keeping warehouse inventory accurate is all about building a more efficient, profitable operation. By implementing automation, you can eliminate stock discrepancies, cut costs, and improve fulfilment speeds. Dexory’s AI-powered warehouse intelligence platform helps warehouses achieve unmatched accuracy and efficiency with real-time data insights.