In the manufacturing industry, time is a precious commodity. From assembly lines to provisioning to facility security and factory floor safety, ensuring smooth and safe operations across an organization is critical.

To streamline manufacturing processes and boost efficiency, forward-thinking manufacturers are increasingly adopting digital technologies like low-code and generative AI (GenAI) solutions. These technologies accelerate innovation and help address challenges such as supply chain disruptions.

“Low code development provides manufacturers a major opportunity to create a more agile and adaptable workforce – and to drive efficiency across the manufacturing value chain.”

The case for digital transformation

Despite the potential of digital tools, research from ServiceNow and Dynata highlights gaps in adoption:

- Only 33% of manufacturers are focused on improving operational technology asset security.

- Just 37% are digitizing factory floors to enhance worker productivity.

- Only 29% are working to improve supplier communication and collaboration, reducing supply chain risk.

These statistics reveal significant opportunities for improvement—and low-code development offers a practical way forward.

Benefits of low-code development in manufacturing

Low-code development empowers manufacturers to enhance agility and adaptability across their value chains. By automating manual processes, enabling rapid response to shifting product demands and accelerating product releases, low-code solutions extend workflow automation and drive enterprise-wide efficiency.

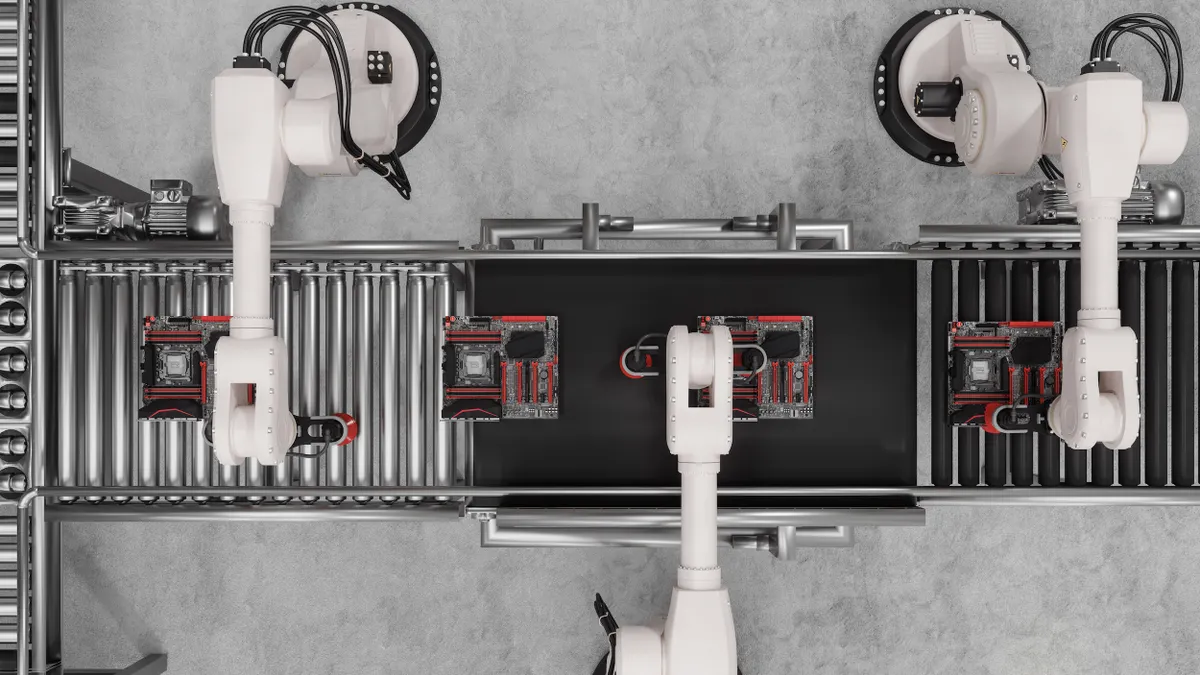

As smart manufacturing and Industry 4.0 continue to grow, manufacturers face the challenge of managing vast data sets generated by IoT sensors on the factory floor. Low-code and GenAI solutions address this by:

- Unifying data across siloed systems

- Automating repetitive tasks

- Seamlessly connecting teams and solutions

Using domain-specific large language models (LLMs), manufacturers can create centralized hubs that collect, analyze and democratize IoT data, offering actionable insights through integration with machine learning models and automation tools.

Low-Code in action: 3 use cases

1. Publishing release management

Complex machinery requires detailed user manuals for safe and effective operation. As machines evolve, updating and republishing these manuals becomes a labor-intensive task. Low-code development enables manufacturers to streamline the manual lifecycle by creating apps that manage release cycles and ensure all stakeholders—from writers to quality assurance teams—are aligned.

2. Automated shift information turnover

Shift turnovers often rely on outdated methods like paper records, leading to inaccuracies that disrupt schedules and hinder productivity. Low-code applications simplify this process by digitizing forms for accurate shift sign-ins and sign-outs. This reduces downtime, minimizes errors and enhances employee satisfaction and safety.

3. Entry lifecycle management

Granting and managing employee access to secure areas is critical for safety and operational efficiency. Traditional methods, such as spreadsheets and emails, often result in delays and lapses in security. Low-code solutions automate entry requests and notifications, ensuring timely updates, reducing security risks and enhancing employee experiences.

Driving innovation at scale

The examples above represent just the tip of the iceberg when it comes to the transformative potential of low-code and GenAI.

Manufacturing is a fast-paced environment. Teams need solutions fast. Waiting on overburdened developers may not be an option. Low-code can empower manufacturers to create powerful software applications that address industry challenges and enable future innovation at an impressive scale.

Find out more about how low-code development helps organizations improve speed, agility and productivity at a fraction of the cost.