Manufacturers are under increasing pressure to accelerate digital transformation in hopes of reducing production bottlenecks, streamlining workflows and reducing downtime. Digital-first approaches, however, aren’t only for achieving efficiency gains on the plant floor. They can also be applied to manufacturing procurement practices.

When procurement struggles to keep pace with business needs, this often creates a disconnect between operational workflows and strategic goals. Digital procurement tools can help bridge the gap. Real-time analytics, automation and purchasing controls can help teams modernize their procurement operations, drive agility and support manufacturing success.

The impact of procurement inefficiencies on manufacturing

Traditional procurement methods have many limitations, and their inefficiencies can create a ripple effect across manufacturing operations, negatively impacting productivity, growth and even worker safety.

How traditional procurement falls short:

-

Visibility gaps: Traditional procurement methods typically operate without centralized control or visibility into spending patterns. These limitations can disrupt production schedules and supply chain reliability. They can also lead to inconsistent pricing for materials and components and overspending caused by fragmented data and reactive purchasing decisions.

- Lack of predictive insights: Legacy procurement methods lack predictive insights that can help procurement teams anticipate and prepare for disruptions, such as material shortages and delays. Without understanding demand fluctuations and supplier reliability, achieving consistent supply availability that keeps production moving and ensures uptime can be challenging.

- Workflow inefficiencies: Outdated procurement systems can slow down financial operations and workflow efficiency, especially when they don’t integrate with existing ERP systems that manage production and inventory. Approvals may be manual, for example, which can lead to delays in sourcing critical materials that disrupt production.

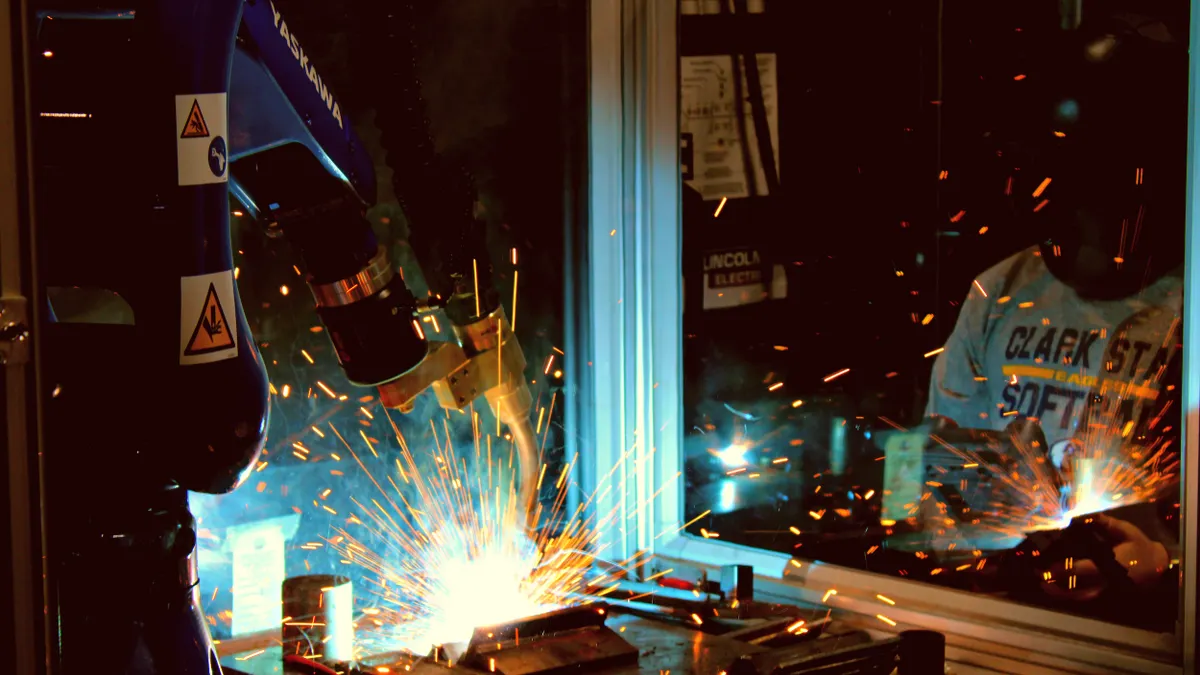

- Inconsistent quality control: Fragmented systems can make it challenging to maintain quality control and ensure that products align with your unique safety standards and are sourced through qualified suppliers. This lack of integration can lead to product inconsistencies and production disruptions.

Enhancing manufacturing efficiency depends on digital procurement

When integrated with existing manufacturing operations, comprehensive digital procurement solutions can lead to streamlined workflows, improved cost control and better decision-making.

Here are five ways digital procurement tools can add value to your manufacturing operations:

1. Establish policies that guide purchasers toward preferred behaviors

When procurement tools allow you to establish and integrate clear procurement policies, you can better enforce best practices, maintain consistency and optimize costs. For example, predefined approval processes can ensure purchases align with your organization’s policies and guidelines to reduce unauthorized spending. Policies can also dictate that buyers can only purchase from preferred and vetted vendors.

2. Gain actionable insights into spending patterns, supplier performance and optimization opportunities

Data-driven insights help improve decision-making and efficiency while reducing disruptions and delays. With digital procurement tools, you can analyze spend patterns and trends, identify areas where cost controls need to be tightened, align with dependable vendors and uncover ways to reduce costs and streamline purchasing.

3. Access fast, predictable delivery and discounts

Ensuring materials arrive on time reduces bottlenecks and helps production flex when needed. Digital procurement tools can help streamline sourcing by providing fast and predictable delivery and volume-based pricing. This can help you procure essential products at lower costs, minimize wasteful spending and shorten the procurement cycle so your organization can scale production on demand.

4. Create a unified digital ecosystem with system integration

When procurement solutions can’t integrate with ERP systems, inventory management and supplier networks, they can create inefficiencies like duplicate work and manual data entry. They can also create data silos, making it harder to optimize inventory and supplier relationships. Finally, they can create missed opportunities for cost savings and faster response to supply chain issues. Integrating these solutions with other vital manufacturing systems can reduce delays, improve decision-making and support automated workflows.

5. Proactively manage budgets at scale

The ability to oversee large budgets is crucial for manufacturers to regulate expenses, optimize resources and continue to grow. Digital solutions can support this by centralizing purchasing across departments and sites, helping procurement leaders identify patterns at the organization level.

Empowering procurement to elevate manufacturing operations

According to the Amazon Business 2025 State of Procurement Data report, 44% of procurement decision-makers believe that the “idea of procurement as functional rather than strategic” is a significant challenge within their organizations.

When manufacturing organizations are empowered by the procurement capabilities mentioned above, they’re often better positioned to drive organizational importance and strategic recognition and can more easily find their seat at the executive table.

From requisition to payment, digital procurement tools can streamline the procurement process from start to finish, powering manufacturing success while ensuring that teams can maintain policy compliance and control.

Learn more at Amazon Business.