Manufacturing leaders today face an urgent paradox: while production demands and asset complexity continue to rise, skilled maintenance talent is harder than ever to find and keep.

With leaner teams under pressure to deliver uptime and reliability, the question becomes: how can plants do more with less? The answer is increasingly tied to technology, specifically, the role of AI in bridging the labor gap, standardizing processes, and giving managers confidence that every task is done right, every time.

The Labor Shortage in Manufacturing

The manufacturing sector is struggling with one of the tightest labor markets in decades. Experienced technicians are retiring faster than new workers can be trained, and recruiting fresh talent is a costly, time-consuming process. Plant managers and reliability engineers are often left with understaffed teams, where the departure of even one technician can mean the loss of decades of tribal knowledge.

This shortage forces plants into a reactive mode, rushing from one breakdown to the next, struggling to meet audits, and relying on a few seasoned employees to troubleshoot complex issues. Without scalable systems in place, every gap in staffing magnifies operational risk.

The New Reality of Maintenance Operations

Today’s maintenance leaders face a new reality: managing operations with fewer hands, tighter budgets, and increasing audit scrutiny. Spreadsheets, binders, and outdated CMMS systems no longer cut it. Processes must be digitized, tribal knowledge must be captured, and tasks must be standardized across teams and shifts.

In this environment, confidence matters as much as speed. A single misstep during an inspection or repair can mean costly downtime, missed production targets, or compliance failures. Teams need real-time insights and tools that not only document what to do, but also guide less experienced technicians through the “how” of maintenance work.

Enter AI-Powered CMMS: Turning Data Into Decisions

AI-powered CMMS platforms represent the next generation of maintenance software. Instead of just storing work orders and asset records, they actively process data, generate recommendations, and simplify decision-making for lean teams.

For example, AI-generated SOPs and checklists ensure that every technician (regardless of experience level) has clear, step-by-step instructions. This standardization minimizes errors, accelerates onboarding, and transforms tribal knowledge into repeatable, reliable workflows.

Meanwhile, AI document analysis takes inspections, reports, or test results and instantly interprets them, merging the findings with IoT sensor data from connected assets. The result is not just more data, but smarter data: insights that help teams troubleshoot quickly, prioritize the right fixes, and stay proactive rather than reactive.

How AI-Powered CMMS Solves the Labor Shortage Challenge

AI-powered CMMS software is designed to tackle the exact pain points that come with leaner teams and high operational pressure. Instead of relying on binders, spreadsheets, or scattered digital tools, these platforms bring knowledge, data, and workflows into one intelligent system.

Unified maintenance intelligence

An AI‑enabled CMMS pulls everything into one place—IoT sensor readings, asset history, prior work orders, manuals, and SOPs—so teams aren’t hunting through binders, spreadsheets, or separate apps. With a single, searchable record per asset, technicians can see what failed, what was tried, and what worked, cutting diagnosis time and improving shift handoffs.

AI that speaks maintenance

Insights arrive in technician‑friendly language, tied to the asset, symptom, and context at hand. Instead of vague alarms, the system explains what’s likely happening and why, then proposes next steps or SOPs. That closes the gap between seasoned experts and newer hires, standardizing quality while accelerating onboarding.

From reactive to proactive

By spotting patterns and anomalies before they escalate, the platform turns emerging issues into scheduled work. Teams shift effort from emergency call‑ins to planned interventions, easing overtime pressure and freeing scarce capacity for higher‑value tasks like root‑cause elimination and continuous improvement.

Built for the floor, not just the office

Mobile‑first workflows deliver the right instruction at the right moment: on the line, at the asset, even offline. Technicians scan an asset, see real‑time condition and history, launch the recommended task, and follow step‑by‑step procedures. The result is less friction between strategy and shop‑floor execution and more consistent outcomes with leaner crews.

Real-World Impact: Doing More With Less

AI is helping plants achieve measurable results, even when maintenance teams are lean. Real world examples show how companies are using data and automation to work more efficiently.

-

Higher uptime with fewer technicians

At Ingredion, predictive insights helped reduce failures across critical machines. With fewer unplanned stoppages, the maintenance team was able to cover more assets without being stretched too thin.

-

Reduced onboarding time

At Fillo Factory, AI generated SOPs and automated workflows gave new technicians clear guidance from day one. Instead of spending months learning the systems, they were able to contribute within just a few days.

-

Improved morale and higher value work

At CZM, automated monitoring took over repetitive checks and manual data entry. This allowed technicians to spend more time on analysis and long term improvements, which contributed to both productivity and job satisfaction.

-

Smarter Decisions With Integrated Insights

At CP Kelco, real time sensor data and inspection reports supported maintenance planning. Leaders could align schedules with production demands, making resource allocation more effective.

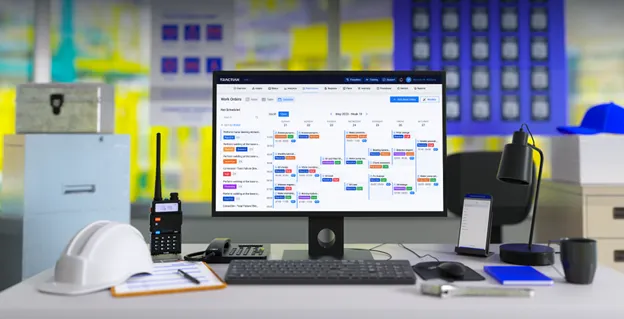

What Sets Tractian Apart

Not all CMMS systems are built alike. Many legacy platforms are complex, require heavy IT overhead, or offer limited data visibility. Tractian’s approach is different:

- AI at the core: from SOP generation to document analysis, built directly into maintenance workflows. We’re also the only CMMS vendor recognized by Forbes AI 50 list, among the most promising artificial intelligence companies.

- IoT sensor integration: combining real-time machine data with preventive maintenance plans, work orders, inspections, and reports.

- Fast time-to-value: deployment measured in days, not months, with no complex integrations required.

- Trusted by teams on the floor: mobile-first design ensures technicians actually use it.

- White-glove support: Engineering team offers personalized, hands-on assistance, backed by real manufacturing experience.

This combination allows Tractian to deliver a single source of truth for maintenance, helping teams transition from reactive to proactive operations seamlessly.

Looking Ahead: The Future of AI in Maintenance

As AI capabilities evolve, maintenance operations will only get smarter. Plants will no longer rely on guesswork to decide when and how to act. Instead, data-driven insights will anticipate failures, prescribe solutions, and ensure every technician, regardless of experience, can deliver consistent, high-quality work.

The maintenance labor shortage is real, but it doesn’t have to define the future of manufacturing. With the right AI-powered CMMS in place, organizations can unlock efficiency, resilience, and growth, even in the face of shrinking teams.

At Tractian, we see this shift happening every day. By combining CMMS workflows, IoT sensor data, and AI-driven insights, we help maintenance teams move from firefighting to foresight. To explore how Tractian can support your operations, take a look at our capabilities and request your free trial.