Cut Manufacturing Costs with AI-Powered Efficiency

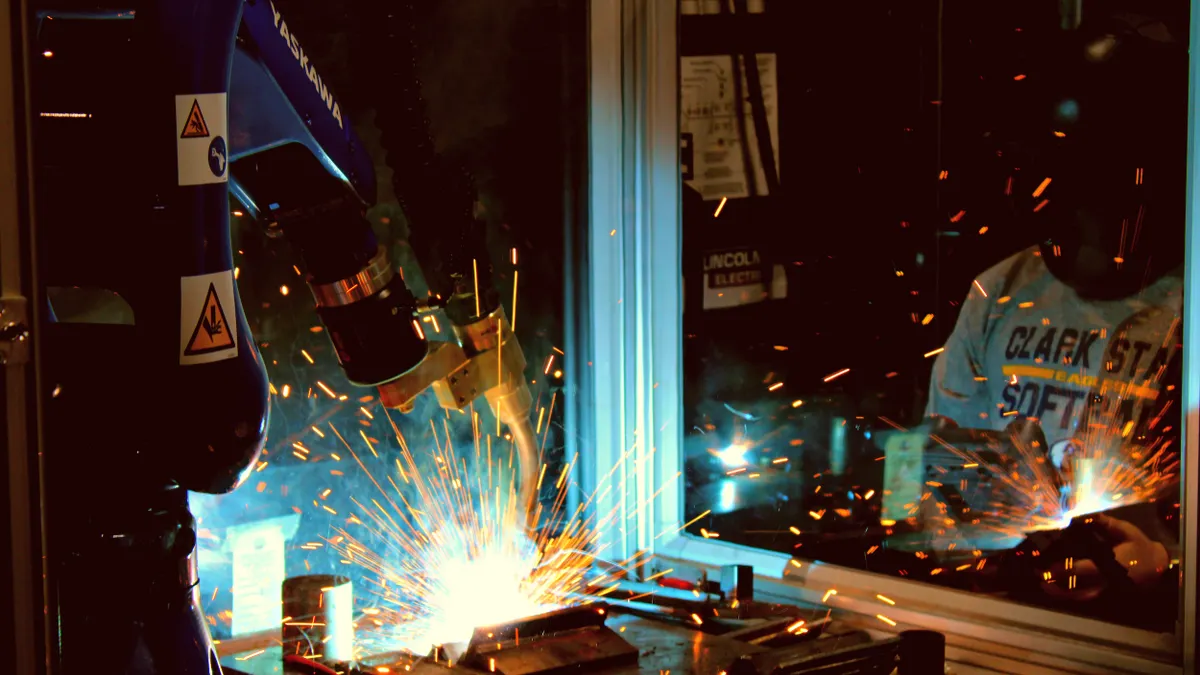

Imagine a bustling manufacturing plant—machines humming, workers busy, and orders rolling in. Yet beneath the surface, inefficiencies like fragmented data, outdated systems, and manual processes inflate costs and hinder performance. Many manufacturers face these hidden challenges daily.

The solution? Embracing AI-powered digital transformation. By modernizing operations, manufacturers can cut costs significantly while boosting productivity and customer satisfaction.

Cost Reduction: The Case for AI in Manufacturing

Manufacturers operate in a hyper-competitive environment with tight margins. Cost pressures are mounting due to fluctuating raw material prices, labor challenges, and rising customer expectations. Addressing these pressures requires more than incremental changes—it demands a shift to smarter, connected operations.

AI-powered technologies, like ServiceNow’s CRM for Manufacturing, can revolutionize cost management. By streamlining workflows, improving visibility, and predicting disruptions, manufacturers can reduce operational expenses and maximize profitability.

According to the American Society for Quality, poor quality management alone can account for 15% to 20% of total sales revenue. Digital transformation helps manufacturers proactively address issues like quality defects, unplanned downtime, and inefficiencies, transforming them into opportunities for savings.

Real-World Impact: A Manufacturer’s Success Story

Manufacturing leaders across industries are already reaping the benefits of AI-powered automation. Here are a few examples:

Streamlined Sales and Quoting

One manufacturer achieved a 30% reduction in the effort required to create quotes by leveraging ServiceNow's platform to accurately generate quotes for complex products and services. This not only saved time but also increased sales opportunities.

Efficient Order Fulfillment

The Kraft Heinz Company transformed its order management process by creating a digital view of day-to-day work. With ServiceNow, they now process over 900,000 orders annually, with real-time, accurate order information. This streamlined process led to a 15% decrease in escalated disputes and faster cash collection.

Enhanced Dealer and Customer Experience

Volvo Construction Equipment, the heavy machinery division of the Volvo Group, automated dealer and internal escalation routing to deliver frictionless customer experience. With 5,000 dealers and more than 7,500 active users on the platform, they've published over 100,000 knowledge articles to increase self-service. The result? A 20% reduction in the time it takes to process warranty claims, with more than 900 cases handled per day.

These success stories demonstrate the tangible impact of AI-powered automation on sales, fulfillment, and customer service. By embracing digital transformation, these manufacturers have cut costs, improved efficiency, and enhanced customer satisfaction.

Four Key Strategies for Cutting Costs

To unlock similar savings, manufacturers should focus on these critical areas:

- Sales Transformation: Streamlining sales operations with AI-driven platforms reduces delays and manual errors, accelerating revenue recognition and minimizing resource waste.

- Service Optimization: Centralizing data from all departments enables faster issue resolution and predictive maintenance, cutting repair costs and improving uptime.

- Proactive Quality Management: Transitioning from reactive to proactive quality processes reduces defects, warranty claims, and associated costs. Advanced tools like AI-driven root cause analysis offer unmatched precision.

- Operational Resilience: Real-time insights and predictive analytics allow manufacturers to optimize resource allocation, anticipate challenges, and avoid costly disruptions.

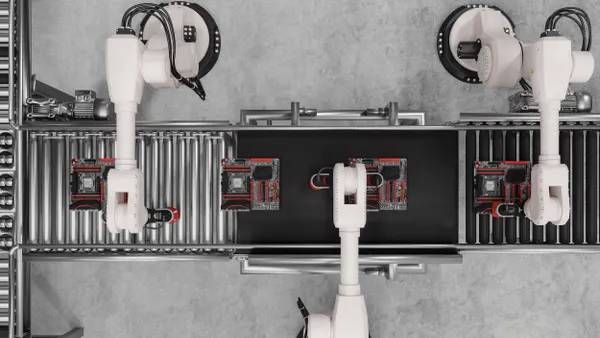

The Future: Intelligent and Cost-Efficient Manufacturing

A connected, intelligent manufacturing environment is no longer a distant dream. With AI-powered tools, real-time data flows seamlessly across systems, enabling faster decision-making and cost-effective operations. From automated order processing to predictive equipment maintenance, every aspect of manufacturing becomes more efficient and less costly.

For manufacturers, the stakes are clear: those who embrace AI-driven digital transformation will lead the way in reducing costs and staying competitive in a dynamic market.

Ready to Drive Down Costs and unleash the Power of AI in Your Manufacturing Operations?

In today's competitive landscape, manufacturers can't afford to leave money on the table. The cost of inaction is simply too high. By embracing AI-powered solutions like ServiceNow's CRM Manufacturing, you can transform your operations, slash costs, and gain a critical edge in the market.

The time to act is now. With Quality 360 and other cutting-edge innovations, ServiceNow empowers manufacturers to achieve unparalleled efficiency, agility, and customer satisfaction. Don't let manual processes and disconnected systems hold you back any longer.

Take the first step towards a more intelligent, cost-effective future. Your bottom line will thank you. Learn more here.