To support the next generation of manufacturing, companies are looking to artificial intelligence, automation and more. But first they have to address challenges around energy and resource use to sustainably take the next leap forward, according to experts at IFS’ Industrial X Unleashed event in New York City last month.

Here are a few takeaways from the discussions.

Electrical grids are at risk of bottlenecking the AI revolution

As more people use electricity to power their homes, heating, transportation and more, the electrical grids are becoming a bottleneck for the energy transition.

At least, that is what Sabine Erlinghagen, CEO of Siemens Grid Software, recalled saying years before AI really took off. As more data centers are built and demand for automation increases, the grids now risk becoming “the bottleneck of the AI revolution,”she said.

Electricity demand is expected to increase 50% by 2050, or roughly 2% per year, driven by data centers and transportation electrification, according to an April report from the National Electrical Manufacturers Association. Centers that handle AI workloads, specifically, are estimated to have demand equivalent to “the entire economy of Japan,” Erlinghagen said, or roughly 125 million people.

As electricity usage increases, a large challenge industries face is the long wait times to connect to the grid. Erlinghagen said interconnection queues have expanded from two to three years to an average of five years now.

“If we say to Microsoft, to any of the AI companies, wait five years until you get your data center, then that AI revolution will go much slower,” she said.

To accelerate the process, Erlinghagen recommended that companies partner with utilities that are inundated with connection requests and find ways to transport more power over the same lines, rather than build new infrastructure.

“If you’ve got to build the grid, it takes years to get the permitting and to get all the steel and copper out there,” she said.

Data center investment is sky-high

Despite grid limitations and power concerns, chipmakers are pouring billions of dollars into constructing data centers to meet growing AI demand.

Microsoft, for example, was spending about $20 billion a year on data center infrastructure in 2022, Darryl Willis, VP of Microsoft’s energy and resources industry, said during the event. Today that number has ballooned to $80 billion a year, he said, or roughly $1.5 billion a week.

Another challenge facing the industry is getting data centers to run with limited to no impact on carbon emissions. Willis said Microsoft is investing in things like green cement made from recycled materials, as well as innovations “around water utilization and micro technologies that cool AI chips.”

“We have got to figure out how to make this work,” Willis said.

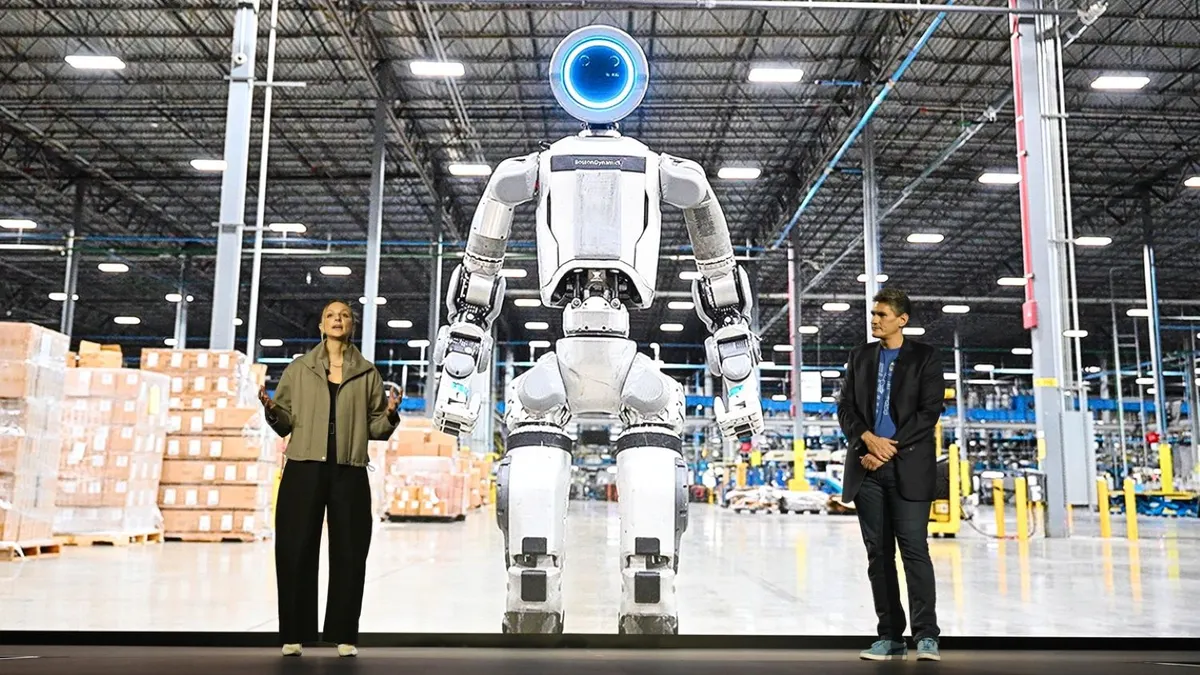

Manufacturers are leveraging automation and robotics for demand-driven production

Prasad Satyavolu, the Americas lead for Accenture’s digital transformation division Industry X, said manufacturers are investing in a hybrid workforce where humans work alongside robots, in part, because it will be key to “virtualizing” the physical environment.

According to Accenture’s global survey of 552 factory managers, about 60% of participants said they were prioritizing automation in the mid-term with a focus on autonomous warehouses, guided vehicles, intralogistics and material handling, as well as mobile robots.

They also noted that AI-driven logistics will be key to helping manufacturers transition from forecast-based production planning to demand-driven manufacturing, allowing them to better “anticipate demand fluctuations, prevent supply chain disruptions and optimize inventory management.”

“This is going to be the future,” Satyavolu said about virtualization and fleet orchestration in the transition to demand-driven manufacturing. He also noted that building digital twins and virtual replicas of the physical environment will significantly reduce deployment costs.

Additionally, the infrastructure and support to build robots for industry at scale will need to be in place. Christian Pederson, chief product officer at IFS, said he expects billions of robotic workers to be built over the coming years.

“All these robots, they have to be manufactured, they have to be serviced, they have to be maintained, there has to be recycling, they need to be upgraded, they are remanufacturing,” Pederson said. “All the things that you do with normal assets that also get produced.”