Mike Ciaccio is the general manager of Polymershapes, a California-based plastics manufacturer that provides materials and services to hundreds of markets. Opinions are the author’s own.

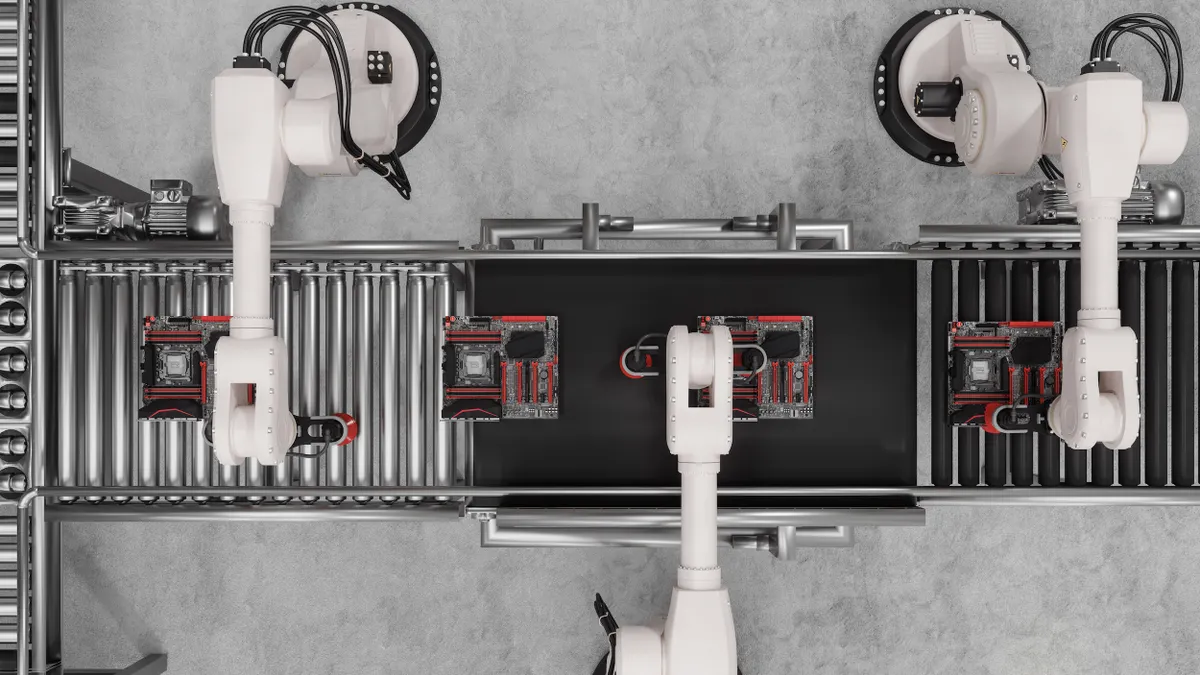

Remember when “aerospace grade” meant something special? Those days of treating it like some unreachable gold standard are over. Walk into any manufacturing plant today and you’ll hear engineers throwing around terms like “traceability protocols” and “statistical process control,” language that used to live exclusively in Boeing’s quality manuals.

This isn’t some distant trend. It’s happening right now, and it’s causing real headaches for manufacturers who thought they could keep doing business the old way. This shift is particularly challenging for the plastic fabrication industry.

The new precision problem

Plastic fabrication has always been more forgiving than precision machining. A little warp here, some surface irregularities there — it usually didn’t matter. The problem is that today's plastic parts sit right next to circuit boards, pressure sensors and precision machinery. A warped housing that nobody cared about five years ago can now throw off an entire assembly.

You can see the industry splitting in real time. Some manufacturers are scrambling to upgrade their capabilities. Others are watching their customer base shrink as buyers move toward shops that can guarantee consistent results.

The pressure is real, and it’s coming from everywhere. Electric vehicle manufacturers don’t want to hear excuses about thermal stress failures in battery housings. Medical device companies expect their plastic components to survive sterilization cycles without question. Even construction contractors are starting to ask about UL-94 ratings for basic enclosures.

Take what happened to Ford in February 2022. The company had to recall over 247,000 Super Duty trucks because underbody thermal insulators were coming loose and damaging aluminum driveshafts. One component failure. A quarter of a million vehicles. That’s the kind of mistake that makes every manufacturer reconsider their quality standards.

These failures don’t happen in a vacuum. They happen because someone figured “good enough” was actually good enough. That calculation doesn’t work anymore.

Traceability: From nice-to-have to non-negotiable

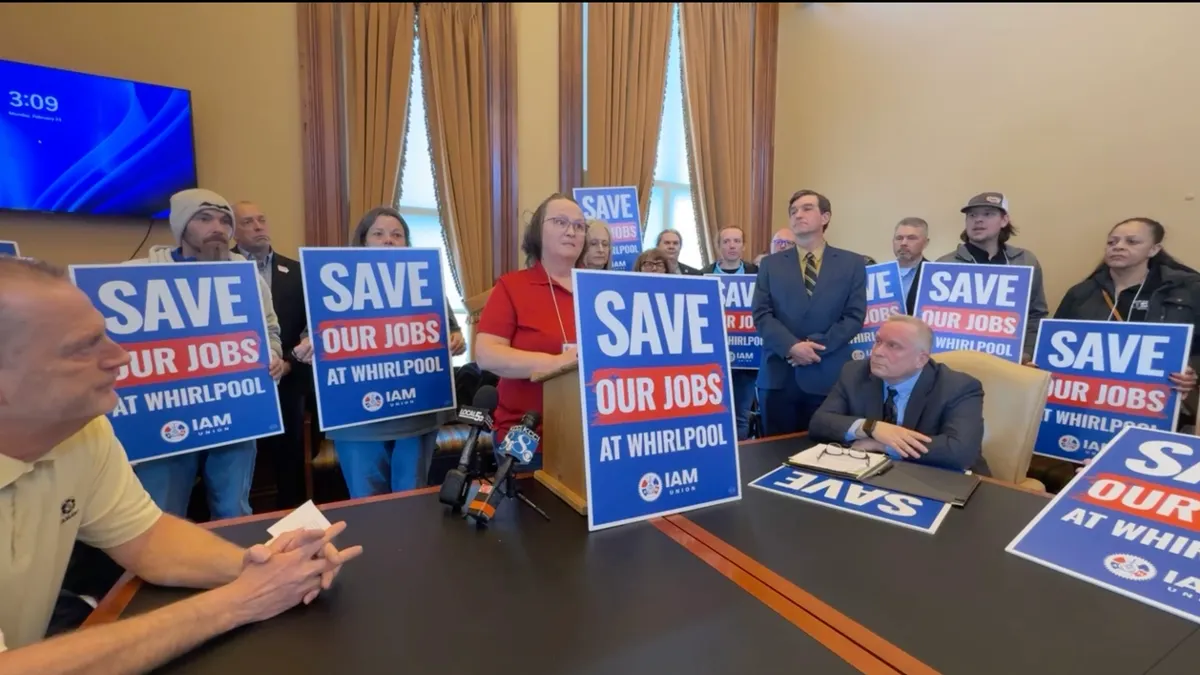

Here’s where things get interesting. Material traceability used to be something only aerospace engineers worried about. Now it’s showing up in purchase orders from companies that make everything from kitchen appliances to playground equipment.

Why the change? Simple math. In high-volume industries, a single defective polymer component can trigger recalls that cost more than some companies make in a year. When failure means millions of dollars in liability, suddenly knowing exactly which resin batch went into which part becomes very important.

Additionally, an uptick in litigation and claims regarding manufacturing defects. Beyond the continually rising costs of legal fees, public sentiment toward corporations is fueling attorneys, courts and juries to seek larger payouts from the companies deemed culpable.

The manufacturers who figured this out early are already seeing the benefits. Companies that implemented full material tracking and formal quality systems report stronger customer relationships and longer-term contracts. It makes sense. When you can prove your processes work, customers trust you with bigger projects.

What actually needs to change

While relationships built upon trust and personal connections are still valuable, they’re no longer enough in today's marketplace. Purchasing managers often come from industries where Six Sigma and ISO compliance are baseline requirements.

Compliance-conscious buyers don’t want to hear about your company’s general commitment to quality. They want data sheets, process flowcharts and statistical evidence.

All of this may mean upgrading your business, which isn’t just about buying new machines. The real work happens in three areas:

- Process documentation becomes critical. Your line workers can’t just follow a checklist anymore. They need to know how their decisions affect the final product, which means more comprehensive training programs.

- Measurement and testing capabilities must improve. Many shops are discovering they need metrology tools that can detect microscopic variations. The equipment exists, but it requires investment and training.

- Record-keeping systems need an overhaul. When a customer calls asking for compliance documentation, too many shops are still saying, “Let me check with production and call you back.” That doesn’t work anymore. The paperwork needs to be ready, organized and complete.

What’s really happening

Here’s the bigger picture: this goes beyond aerospace standards and is moving into other markets. It’s a fundamental shift in how we think about plastic components. From surgical instruments to building materials to autonomous vehicle parts, plastic is being asked to perform at levels that were unimaginable 20 years ago.

The manufacturers who succeed won’t necessarily be the ones with aerospace experience. They’ll be the ones who learned the lessons from aerospace and applied them while their competitors were still treating plastic like a commodity.

The transition isn’t optional anymore. Upgrading equipment, training and hiring skilled personnel is expensive, but the cost of not changing is now higher. Manufacturers who move early will capture market share. Those who wait will find themselves negotiating from a place of weakness.