Acquisitions are a fact of life for many manufacturing companies, sometimes leading to facility closures or difficult situations for employees when investors move on. The Manufacturing Revitalization Corporation of America, a private equity firm, says it’s taking a different approach.

MRCA, launched in 2021 by brothers Jason and Keven Azevedo, says its exit strategy will be to help set up an employee stock ownership plan rather than flip the companies to another investor.

So far, MRCA has acquired multiple decades-old manufacturers — Hoffman Tool and Die, Hose Assemblies, Morris Manufacturing, TMI, Wells and Wisconic. They collectively employ approximately 400 people in four states in the Midwest and central U.S. The firm has also scaled with multiple brand acquisitions, including this spring when it announced the purchases of furniture company Semi Exact and composting system companies Subpod and Hungry Bin. They joined other direct-to-consumer brands such as Bottle Buddy and Crisp.

Part of the group’s strategy is to bring together companies with different manufacturing capabilities and supply chains — such as plastic injection molding and metal working — to help scale production for various DTC brands. The latter part of the business is now being led by Semi Exact cofounder Elton Rivas.

Manufacturing Dive spoke with Rivas and Jason Azevedo in July about MRCA’s investment strategy, domestic manufacturing, supply chain shifts, tariffs and more.

This conversation has been edited for length and clarity.

MANUFACTURING DIVE: Jason, how did MRCA come about and what motivated you to take a different approach to private equity investments?

JASON AZEVEDO: We grew up in a factory household. Our father worked graveyard [shift.] We got to see the ugly side of what happens when buyouts happen. So he'd worked at a company for about 29 years. In the last seven or eight years that he worked there PE firms and M&A firms bought them and sold them almost once a year.

Basically, they would go in and take the assets they want, strip mine everything and then sell it off to the next person who would take the assets they wanted, move them on and just keep on that cycle until one day everyone lost their jobs, there was no factory. And it was a profitable plan.

We started our own manufacturing companies when I was 15, and said, "If we're going to do this, we're going to do it different." And then when we got into the process of acquiring companies, that ethos has always stayed. There's a lot of really, really great companies that have been built over usually generations within these families, and we really want to make sure we preserve that backbone of the industry.

How is MRCA’s exit strategy different than a standard PE firm that will sell the assets in a certain number of years, and how do you think about your average holding period?

AZEVEDO: So our exit strategy is significantly employee focused. Our goal is to leave the power of the organizations in the hands of the employees that have built them over these generations. We're looking at doing an [employee stock ownership plan] so that all of the employees will truly have a seat at the table as decisions are being made for the future of the organizations.

One of those hard parts is we come in saying we're going to preserve the legacy, but then what happens after our exit, and who's there to preserve it? We couldn't think of anybody better to preserve it than the people that are actually part of it.

We don't have a set holding period. One of the things that we've always said is that the entire portfolio will go together. So an injection molding plant in Wisconsin will benefit a machine shop in Indiana and they'll move, for lack of a better term, as a conglomerate. So even after exit, they've got the firepower together.

Elton, Semi Exact is one of the more recent additions to MRCA. What has that meant for you in terms of integration and new opportunities?

ELTON RIVAS: I think we're focused on the transition period, still. I have the unique viewpoint here of looking at other brands that have been recently tucked in, and helping MRCA to build that foundation to make sure we have a good, smooth transition. So that's piece one.

I think piece two is starting to figure out what do we have that we can bring to the table for direct-to-consumer brands or for other tuck-ins that are looking to scale their operations. How do we use all the new tools that are at our fingertips and think about this convergence of industry 4.0 and DTC 3.0? What that means is trying to figure out how to stay on the front burner of all of the AI-enabling tools to make sure that the customer personalization is unique, authentic and sticky.

There's two pieces of that puzzle. One is the foundation on making sure we continue to make and ship the great quality products. The other is building a tool set to make it easy for the consumer to find out about whatever those brands are, choose the appropriate personalization for the brand, and then get that product information and shipping and have a really great experience.

What has MRCA’s investment meant for companies that were acquired in prior years? Have you found opportunities to expand over time, or grow volumes, with new production facilities?

AZEVEDO: Every acquisition we have ends up growing volume, and part of that is just coming in with fresh energy. When you've been running a company for 40 years, you sometimes just say, “Hey, I'm happy with where I'm at, I really don't feel like pushing anymore.”

So a lot of that is ... where we can find that synergy between groups. One team is really good at automation, but the other team is really good at process. Well, can we bring the automation team to the one that's good at process, take the process team to the automation facility, and then really start using best practices.

In a lot of these smaller organizations, because they didn't have 500 to 600 people with them, they don't have 500 to 600 careers to pull against. Now we’re able to say, “Go talk to Al, he's actually done this for 20 years. He can help you with that problem.” That's really where the magic comes.

All of our companies are heavily pushed to work with each other and share ideas. The thing you think is super simple is what the other guy thinks is super hard. So get those conversations going and get people to realize that they are experts in their space.

In thinking about future growth, is there an ideal size for companies that you see as best suited for MRCA?

AZEVEDO: Everything is different. Like with these tuck-in brands that Elton mentioned, they're on the smaller side, but they tuck in really nicely to the organization. We've got a lot of lower-middle market stuff, which is our core acquisitions. But then we've got some whales that we're constantly in discussion with that align with the vision of MRCA.

We're not acquiring a billion-dollar company tomorrow, but possibly $100 million to $200 million. We just had one reach out to us a couple weeks ago that's a $100 million company in their fourth generation.

So it varies. What we're really looking for is who's the right fit. We've gotten really, really good at saying no a heck of a lot more than we say yes. And not because they're bad companies, but they're just not the right fit.

Elton, what’s a good profile for other DTC companies that could benefit from working with MRCA?

RIVAS: I think what's opportunistic for brands that are looking for production partners is the fact that it's extremely hard to start a domestic manufacturing company.

There's hundreds of billions that are pumped into early-stage tech startup ecosystems. That same infrastructure is not there for people that want to build some sort of tangible product or durable good.

With MRCA, as Jason mentioned, there's a complement of manufacturing prowess. Where else can you go and find a machine fab shop or a metal working shop and then also go find plastic injection molding, then find somebody that's doing the hoses and assembly for things like that, then find somebody that has customers that are very large scale in the Fortune 100, and then also has a division and a team that's focused on consumer.

It's the unique mix of manufacturing expertise that MRCA brings to the table all under one umbrella, operated through these individual portfolio companies. It's very hard to find that when you're bringing a product to market.

We often hear that higher labor costs are a hindrance to domestic manufacturing, but at the same time we hear about domestic production benefits in terms of quality control and supply chain management. Jason, what do you think people may be missing if they haven’t pursued domestic investments yet?

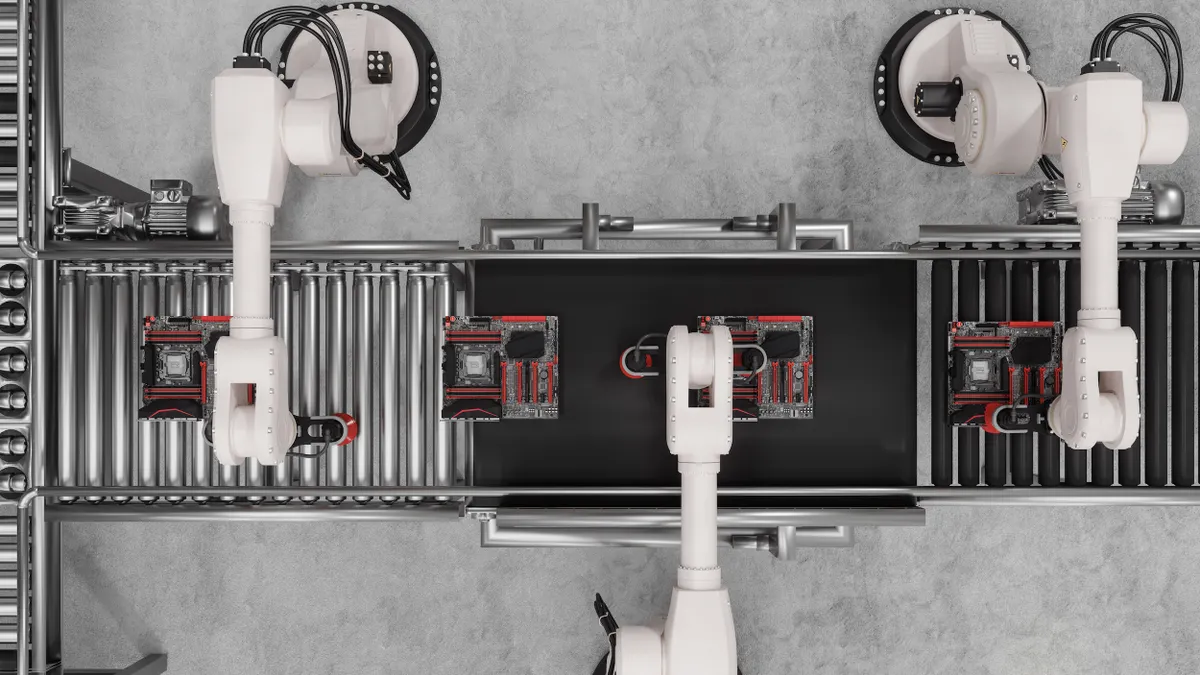

AZEVEDO: I mean the reality when we talk about any foreign production — and let me just call a spade a spade, we're talking about Asian production — the trump card that they've had historically is labor. And what I think everybody missed was that computers and automation suddenly exist. The rest of the world figured it out.

U.S. manufacturing went through the same thing over the last 20 to 25 years, and what happened was we took away the labor issue. For a lot of items, you're no longer hand hammering something.

At first it was incredibly expensive to automate, so everyone said, “OK, that's only on super high volume.” Well, in the last 10 to 15 years, what's happened is that cost has drastically dropped, just like every other piece of technology has, and its versatility went drastically up.

Instead of purpose-built everything, and it takes years to automate, you've got programs like cobots where now you can automate something in 10 minutes and move on.

The real complexity about moving things to domestic manufacturing is when products left the U.S. in the ‘80s, ‘90s, they were made using a single process. When they're coming back, they're no longer single-process items. Everything has way more complexity.

Our view with MRCA was we need to actually be able to get as close to a completed product as we can for somebody, so that we can match what modern products look like, and that's why we are so wide.

RIVAS: All of the things that have happened with production automation, innovation in those realms has also been parallel over the past 40 years with the change of consumer choice and business choice.

Social media enabled real-time information. That led to personalized production demand. “I want this how I want it, and I want it now.” Well, it's really hard to do personalized production in a global supply chain when you've got different components coming together, and the consumer wants it faster, faster, faster, faster.

The consumer also has been willing to pay slightly more. So I think those things have changed, where it's not just a race to the bottom for every product. There's a uniqueness that comes with that brand story, or those products, or some of those niches that they're in.

Niches have also gotten bigger. They're not just a small $10 million market opportunity. A niche is now a billion-dollar opportunity. So I think all of those things have changed, and now we're seeing that sustainable, profitable growth that's driving that need to actually reshore and nearshore stuff.

How are tariffs and the new federal tax law changing your business for better or for worse?

AZEVEDO: The first thing I told our team was, no matter what happens, don't get excited. And no matter what happens, don't get sad. We're not here for one administration. We're not here for two administrations. We believed in this before it was cool. We're going to believe in it probably after it's cool.

For one of our facilities, steel prices went up. At another facility, the mill called us and reduced our pricing. There's a ton of noise.

The one good thing, and this happened during COVID too, is it has made a lot of sense to manufacture in the U.S. for the last 10 or 15 years. And it's making more and more sense by the year. What COVID did, and what the current administration and the current tariff talk has done, is it forced people to go look at American manufacturing.

So it's a catalyst. But we don't bank on this policy adding value to us. Because as quick as a policy comes, it can go just as quick. It's really about opening people's minds, making them break down that constant nagging idea in the back of people's brains that it's all about low labor. It's not. It's really about where does it make the most sense to produce an item?