Dive Brief:

- Cloud and AI software provider IFS said that it’s teaming up with Anthropic, a large language model developer, to scale artificial intelligence that helps frontline workers detect machinery and systems issues they might otherwise miss.

- As part of the partnership, IFS is using its industrial program Nexus Black to launch Resolve, a tool that places AI directly in the hands of technicians and field workers across aerospace and defense, manufacturing, energy, utilities and other major industries.

- Resolve leverages Anthropic’s Claude LLM to analyze thousands of equipment images, interpret sensor readings and recognize patterns to “catch problems before they become failures,” according to a news release.

Dive Insight:

As manufacturers look to make the switch from analog to digital operations and processes, they can be limited by the types of technology available to them. Several are ramping up AI adoption for robotics that can do repetitive tasks, but according to IFS, there is untapped demand for specialized software tailored for technicians, field workers and more.

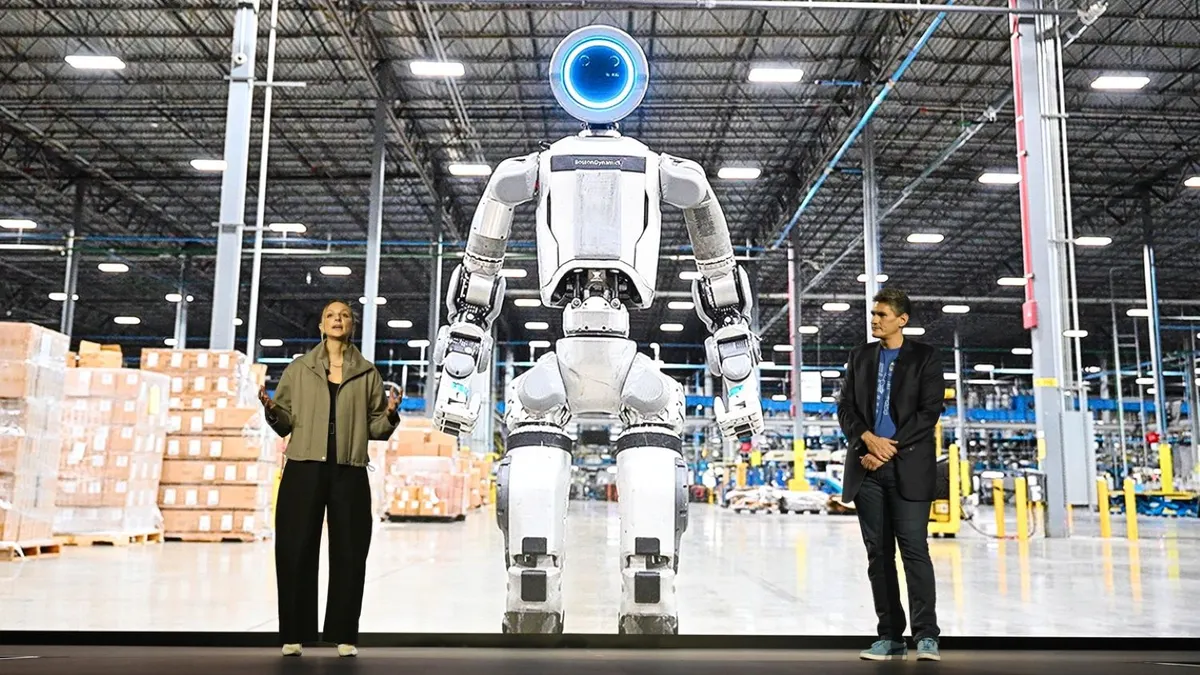

Instead of the generic AI tools used by white-collar workers, industrial companies need tools that can solve a “range of hard problems” to prevent factory downtime, Kriti Sharma, CEO of IFS Nexus Black, said at the software provider’s inaugural Industrial X Unleashed event in New York City on Thursday.

Distillery William Grant & Sons, the makers of Grant’s whisky and Hendrick’s gin, has been piloting Resolve at one of its factories in Scotland to read complex plant schematics and predict potential failures before they happen. Using the tool, technicians can diagnose faults by capturing the sound of a rattling pipe, video of a part moving strangely or pressure fluctuations, according to a news release.

The distillery has since cut downtime and boosted output, with estimated cost savings of 8.4 million pounds ($11.1 million) per year at the one location, Sharma said.

IFS has also deployed Resolve at an airport hangar in the Middle East. Sharma said the technology can break down complex documents and highly specialized expertise into a clear sequence of steps for workers to understand.

“[It] gives you step-by-step repair guidance so a junior engineer can act like one with 20 years of experience, and it learns from every job you do with it,” she said.